Co-robots enter a period of acceleration, Techsoft Robots helps companies quickly break robot barriers

Date:2021-01-19

The global epidemic in 2020 forces the manufacturing industry to speed up the process of automation to maintain efficient production, which has led to the re-enlargement of the blue ocean market for robots, especially in China. According to statistics, from January to October, China's industrial robot output exceeded 180,000 units, an increase of 21% over the same period last year. In the first 10 months, robot manufacturers have nearly 40 billion U.S. dollars in revenue and realized 920 million U.S. dollars in profits. This is a rare growth industry this year. In the context of China's manufacturing transformation, the automation process is only the key to rapid progress, and the continuous growth of industrial robots is expected to continue.

As a branch of industrial robots, the market space of co-robots has a broader market space than traditional industrial robots because they are simple to install, flexible to deploy, and able to cooperate with people. Statistics show that although the global robot sales volume was 37W units last year, a 12% decrease from the same period last year, the market share of co-robots is increasing year by year. It is estimated that by 2027, the global co-robot market will reach 5.6 billion, accounting for 30% of the total robot market.

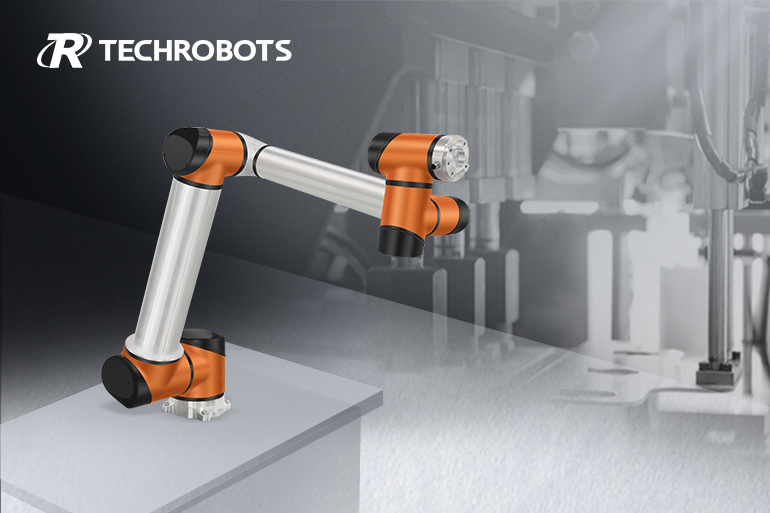

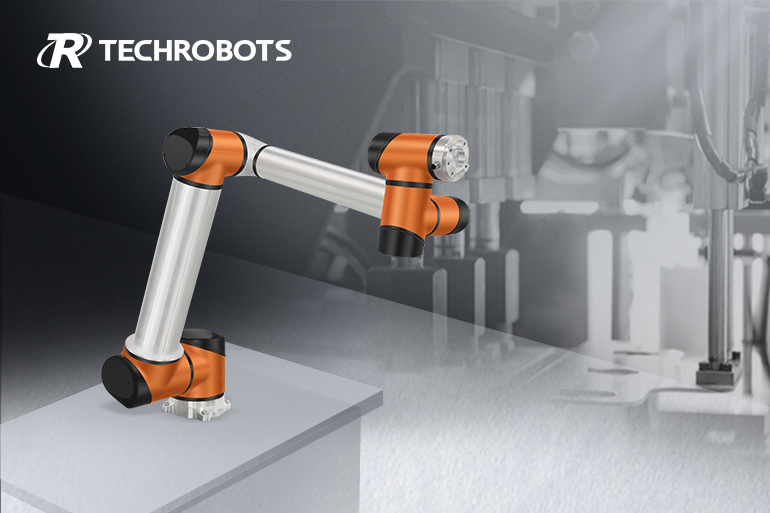

Compared with traditional robots, co-robots (Techrobots) are still an emerging market and are still in an uncertain state. Both foreign veteran manufacturers and local Chinese companies have the opportunity to take a share of the incremental market of "machines for people". At this stage, manufacturers of co-robots (Techrobots) hope to quickly establish core competitiveness and barriers. What are the key capabilities? It is a basic requirement to realize the safety of human-machine cooperation without sacrificing efficiency and low cost. On this basis, manufacturers with independent technology and the development of flexible intelligent co-robots (Techrobots) will have greater potential.

Safe production: not at the expense of low efficiency and high cost

For "isolated" traditional industrial machines such as safety guardrails, due to the particularity of human-machine integration, the collaborative machines are safer. There is no need to implement production operations on the basis of guaranteeing machine safety like traditional industrial robots. Most co-robots have the ability to carry out collision warning through perceptual technologies such as force perception and vision. When the human body approaches or encounters an obstacle, the robot stops running to ensure human safety and realize the collaborative operation of humans and machines in the same space.

However, in actual production, the safety indicators of collision detection will be affected by load and speed, which is why most co-robots currently have only 5-10 kg load-level products. With the increase of power, the difficulty of safety control of traditional force perception is greatly increased, and the cost of visual perception will greatly increase, which will eventually lead to the decline of actual safety or the realization of relative safety, but the cost greatly reduces efficiency.

Flexible intelligence: rigid demand for automated flexible production

In the past, the term "machine replacement" has been used in industry, and human values cannot be completely replaced in a short time. This is neither realistic nor economical. Therefore, "human-machine cooperation" is the correct way to open it in the future. Therefore, only when efficiency and safety are satisfied can co-robots have the opportunity to truly invest in large-scale production scenarios.

Will co-robots (Techrobots) replace traditional industrial robots? Do not! In the production process, the scene is complex and diverse. In a small and flexible environment, co-robots will cooperate with traditional industrial robots to maximize efficiency, and will not completely replace manual or traditional industrial robots. Co-robots (Techrobots) have their own "task", "inconvenience", "not suitable", "not suitable" to use traditional industrial manipulators, or to integrate into the market as an indispensable part of the comprehensive automation transformation process.

Scenario extension: domestic technology manufacturers have outstanding advantages

The dominant nature of technology is the core competitiveness of global intelligent manufacturing. Technology-driven manufacturers have greater endurance in this round of the competition. At the same time, the technology needs to have enough market "soil" to release value. With the continuous expansion of the application scenarios of co-robots in China and the increase of market capacity, huge market development space will appear. Therefore, in the next five years, the advantages of China's co-robot manufacturers with strong independent research capabilities will be highlighted.

From the perspective of industrial applications, the industrial field will still be the leading market for co-robots (Techrobots), including automobile manufacturing, 3C electronics, logistics, etc. However, with the development of lightweight and miniaturization, co-robots (Techrobots) have great potential in fields outside of industry such as medical care, logistics, education, scientific research, and commercial applications.

With the development of 5G communication and artificial intelligence technology, future co-robots will inevitably penetrate into various subdivided application fields, and will further integrate sensing technologies. This means that co-robot manufacturers need to invest more technical force to develop products to seize the market in different fields.

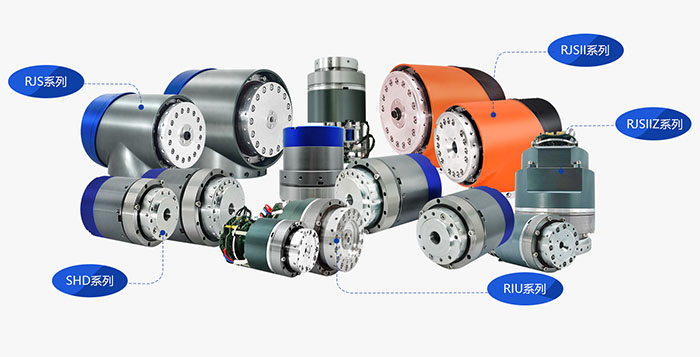

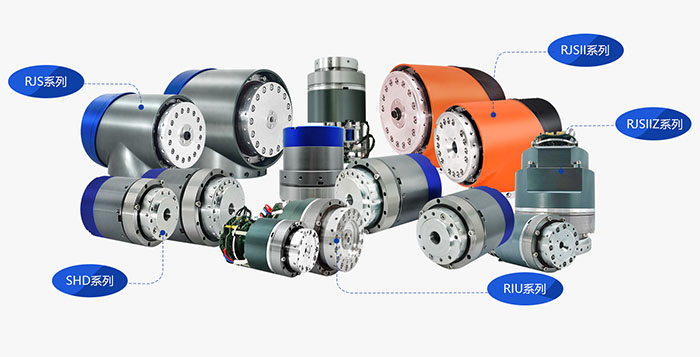

However, as a domestic professional R&D robot joint module manufacturer, Techrobots can better help domestic robot manufacturers, save a series of investment in robot joint module R&D, design, procurement, parts assembly and testing, and labor costs, and help companies quickly build Branded co-robots can be put into the market quickly, accelerate the market layout, and recover the return on investment.

As a branch of industrial robots, the market space of co-robots has a broader market space than traditional industrial robots because they are simple to install, flexible to deploy, and able to cooperate with people. Statistics show that although the global robot sales volume was 37W units last year, a 12% decrease from the same period last year, the market share of co-robots is increasing year by year. It is estimated that by 2027, the global co-robot market will reach 5.6 billion, accounting for 30% of the total robot market.

Compared with traditional robots, co-robots (Techrobots) are still an emerging market and are still in an uncertain state. Both foreign veteran manufacturers and local Chinese companies have the opportunity to take a share of the incremental market of "machines for people". At this stage, manufacturers of co-robots (Techrobots) hope to quickly establish core competitiveness and barriers. What are the key capabilities? It is a basic requirement to realize the safety of human-machine cooperation without sacrificing efficiency and low cost. On this basis, manufacturers with independent technology and the development of flexible intelligent co-robots (Techrobots) will have greater potential.

Safe production: not at the expense of low efficiency and high cost

For "isolated" traditional industrial machines such as safety guardrails, due to the particularity of human-machine integration, the collaborative machines are safer. There is no need to implement production operations on the basis of guaranteeing machine safety like traditional industrial robots. Most co-robots have the ability to carry out collision warning through perceptual technologies such as force perception and vision. When the human body approaches or encounters an obstacle, the robot stops running to ensure human safety and realize the collaborative operation of humans and machines in the same space.

However, in actual production, the safety indicators of collision detection will be affected by load and speed, which is why most co-robots currently have only 5-10 kg load-level products. With the increase of power, the difficulty of safety control of traditional force perception is greatly increased, and the cost of visual perception will greatly increase, which will eventually lead to the decline of actual safety or the realization of relative safety, but the cost greatly reduces efficiency.

Flexible intelligence: rigid demand for automated flexible production

In the past, the term "machine replacement" has been used in industry, and human values cannot be completely replaced in a short time. This is neither realistic nor economical. Therefore, "human-machine cooperation" is the correct way to open it in the future. Therefore, only when efficiency and safety are satisfied can co-robots have the opportunity to truly invest in large-scale production scenarios.

Will co-robots (Techrobots) replace traditional industrial robots? Do not! In the production process, the scene is complex and diverse. In a small and flexible environment, co-robots will cooperate with traditional industrial robots to maximize efficiency, and will not completely replace manual or traditional industrial robots. Co-robots (Techrobots) have their own "task", "inconvenience", "not suitable", "not suitable" to use traditional industrial manipulators, or to integrate into the market as an indispensable part of the comprehensive automation transformation process.

Scenario extension: domestic technology manufacturers have outstanding advantages

The dominant nature of technology is the core competitiveness of global intelligent manufacturing. Technology-driven manufacturers have greater endurance in this round of the competition. At the same time, the technology needs to have enough market "soil" to release value. With the continuous expansion of the application scenarios of co-robots in China and the increase of market capacity, huge market development space will appear. Therefore, in the next five years, the advantages of China's co-robot manufacturers with strong independent research capabilities will be highlighted.

From the perspective of industrial applications, the industrial field will still be the leading market for co-robots (Techrobots), including automobile manufacturing, 3C electronics, logistics, etc. However, with the development of lightweight and miniaturization, co-robots (Techrobots) have great potential in fields outside of industry such as medical care, logistics, education, scientific research, and commercial applications.

With the development of 5G communication and artificial intelligence technology, future co-robots will inevitably penetrate into various subdivided application fields, and will further integrate sensing technologies. This means that co-robot manufacturers need to invest more technical force to develop products to seize the market in different fields.

However, as a domestic professional R&D robot joint module manufacturer, Techrobots can better help domestic robot manufacturers, save a series of investment in robot joint module R&D, design, procurement, parts assembly and testing, and labor costs, and help companies quickly build Branded co-robots can be put into the market quickly, accelerate the market layout, and recover the return on investment.