The benefits of co-robots to manufacturing

Date:2020-10-29

Today, most manufacturing industries face huge challenges, but they can be solved by co-robots. Currently, the biggest challenge every company needs to solve is workplace safety. Many companies spend a lot of money every year to pay for the medical expenses of their employees.

Except for medical expenses, most employees are absent for several days due to illness and injury. The absence of an employee at the workplace will incur direct and indirect costs, thereby affecting the financial status of the company.

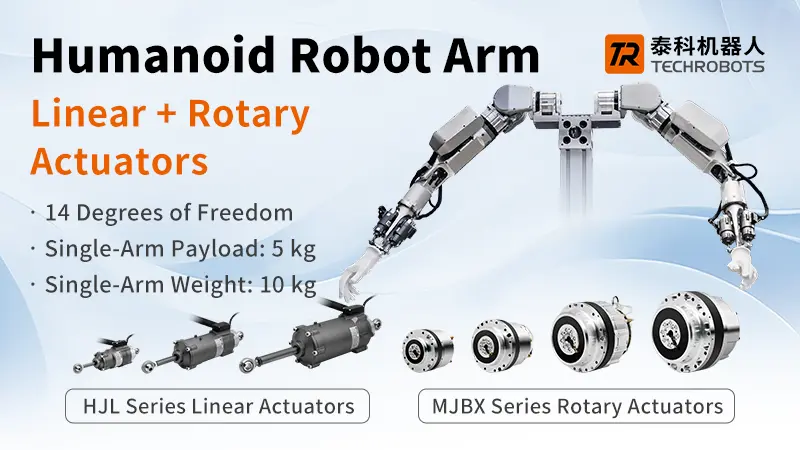

The universal co-robotic arm is designed to help companies reduce workplace injuries and related costs. Co-robots are an ideal substitute for human beings. It does not require medical plans or choices.

What are the benefits of using co-robots?

What are the benefits of using co-robots?

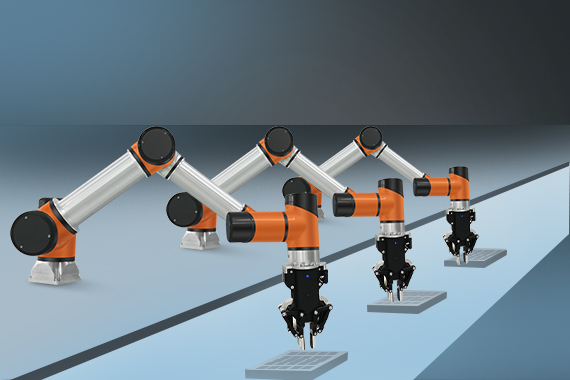

There are many benefits to using co-robots in this industry. Although the initial cost of installing a single collaborative robot is high, the benefits are huge. The advantages of using a universal robot are as follows:

1. Co-robots improve safety in the workplace

Manufacturing has many processes that pose risks to humans. Heavy work such as weightlifting can cause physical harm to employees. Employees are also in danger of falling from heights. Other processes, such as welding, require high temperatures, which cannot be handled by humans.

Spraying can also release harmful fumes and affect human health. To avoid all these health complications, companies should hire a general collaboration department. Co-robots can complete all these tasks without health problems. Design a single arm to accurately handle all manufacturing processes. The co-robot machine can effectively lift, weld, spray, and transport products from one point.

2. Reduce production costs

For many industries, one of the biggest challenges is production costs. It is best to hire several employees to perform various tasks in the production plant. However, you can accomplish these tasks precisely with robots. Co-robots transfer from one job to another, thereby reducing production time. The use of co-robots can also reduce the cost of wages, insurance, and benefits paid to workers.

3. Shorten the production time

Time is money for businesses. Co-robots reduce production time, thereby reducing production costs. Unlike humans, co-robots can work faster and more continuously. The co-robot never rests and can work 24 hours a day. When companies use co-robots to perform production tasks in factories, they can save a lot of time, thereby saving overall production costs.

4. Improve productivity and growth

4. Improve productivity and growth

The lack of skilled labor has greatly affected productivity and growth. It is expensive for a qualified person to perform certain tasks in the production department. A shortage of experienced labor will reduce production efficiency, thereby affecting overall productivity and growth. The solution to this problem is a universal co-robot. The joint manipulator is programmed to handle all production tasks in the industry.

Co-robots can work automatically and continuously, thereby increasing production. Co-robots never need to ask for leave or leave. Co-robots will never get sick or injured. They never get tired. Therefore, they will continue to work. Manufacturing using general-purpose robotic arms replaced its productive labor. These industries have grown over time.

5. Position as a skilled worker

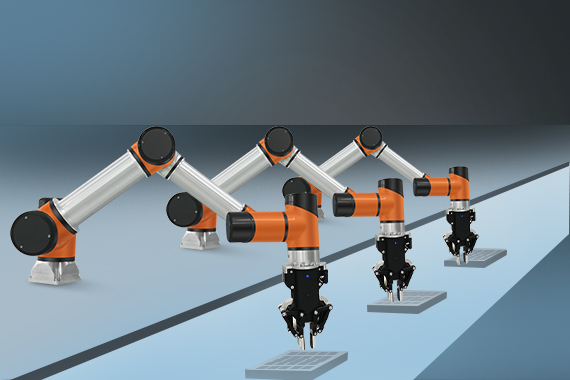

One problem in manufacturing is the need for skilled labor. Many departments lack skilled labor, and if one of the employees leaves, it will be difficult to fill this vacancy. The lack of qualified personnel may cause the entire production department to stagnate. Co-robots can be used to fill positions for skilled workers. Co-robots work more accurately than humans, thereby increasing output.

Except for medical expenses, most employees are absent for several days due to illness and injury. The absence of an employee at the workplace will incur direct and indirect costs, thereby affecting the financial status of the company.

The universal co-robotic arm is designed to help companies reduce workplace injuries and related costs. Co-robots are an ideal substitute for human beings. It does not require medical plans or choices.

There are many benefits to using co-robots in this industry. Although the initial cost of installing a single collaborative robot is high, the benefits are huge. The advantages of using a universal robot are as follows:

1. Co-robots improve safety in the workplace

Manufacturing has many processes that pose risks to humans. Heavy work such as weightlifting can cause physical harm to employees. Employees are also in danger of falling from heights. Other processes, such as welding, require high temperatures, which cannot be handled by humans.

Spraying can also release harmful fumes and affect human health. To avoid all these health complications, companies should hire a general collaboration department. Co-robots can complete all these tasks without health problems. Design a single arm to accurately handle all manufacturing processes. The co-robot machine can effectively lift, weld, spray, and transport products from one point.

2. Reduce production costs

For many industries, one of the biggest challenges is production costs. It is best to hire several employees to perform various tasks in the production plant. However, you can accomplish these tasks precisely with robots. Co-robots transfer from one job to another, thereby reducing production time. The use of co-robots can also reduce the cost of wages, insurance, and benefits paid to workers.

3. Shorten the production time

Time is money for businesses. Co-robots reduce production time, thereby reducing production costs. Unlike humans, co-robots can work faster and more continuously. The co-robot never rests and can work 24 hours a day. When companies use co-robots to perform production tasks in factories, they can save a lot of time, thereby saving overall production costs.

The lack of skilled labor has greatly affected productivity and growth. It is expensive for a qualified person to perform certain tasks in the production department. A shortage of experienced labor will reduce production efficiency, thereby affecting overall productivity and growth. The solution to this problem is a universal co-robot. The joint manipulator is programmed to handle all production tasks in the industry.

Co-robots can work automatically and continuously, thereby increasing production. Co-robots never need to ask for leave or leave. Co-robots will never get sick or injured. They never get tired. Therefore, they will continue to work. Manufacturing using general-purpose robotic arms replaced its productive labor. These industries have grown over time.

5. Position as a skilled worker

One problem in manufacturing is the need for skilled labor. Many departments lack skilled labor, and if one of the employees leaves, it will be difficult to fill this vacancy. The lack of qualified personnel may cause the entire production department to stagnate. Co-robots can be used to fill positions for skilled workers. Co-robots work more accurately than humans, thereby increasing output.