Why do we need collaborative robots in manufacturing?

Date:2020-10-28

Generally speaking, in terms of robotic automation, Jay Baron, CEO of the Automotive Research Center, said: "Without this automation, our factory would have been obsolete a long time ago. Automation is essential for safety, quality, and productivity."

This reflects the strong pressure that companies face in implementing technology to keep up or surpass the competition.

As more and more companies turn to robotic automation for success, now is the time to evaluate inventory, evaluate applications, and make smart business decisions. Without a unified solution, the automation of the manufacturing process is a complex problem.

Some processes require co-robots, which are robots designed to share workspaces with human workers, but they are actually more suitable for traditional industrial robots.

Some processes require co-robots, which are robots designed to share workspaces with human workers, but they are actually more suitable for traditional industrial robots.

The global co-robot market is expected to grow from US$175 million in 2016 to US$3.8 billion in 2021. This is why manufacturers really need to understand the facts before they can jump into the implementation of co-robots.

Co-robot

The original intention of the term co-robot is to represent an unattended, easy-to-integrate co-robots. These robots usually perform repetitive or unsafe tasks, while humans perform tasks upstream or downstream.

Perform higher-value manual tasks. They are very flexible, capable of performing a variety of different tasks and working side by side with humans, rather than replacing them.

Co-robots provide viable automation solutions for small and medium-sized companies because they usually have fewer upfront costs, at least at first glance.

The robotics industry does not recognize that a co-robot is a separate entity, but defines industry safety standards for humans and robots in the same production workshop.

This is an important difference, because new robot implementers may assume that any co-robot can be automatically and safely used next to humans, but in reality, this can only be determined through a comprehensive risk assessment.

If risks are not properly predicted initially, some plant managers may be surprised to find that they need expensive fences.

The result of the risk assessment is that the added safety features may cause the co-robot to run very slowly or stop multiple times.

Industrial robot

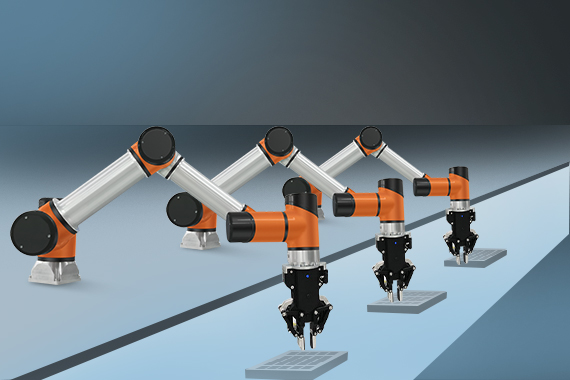

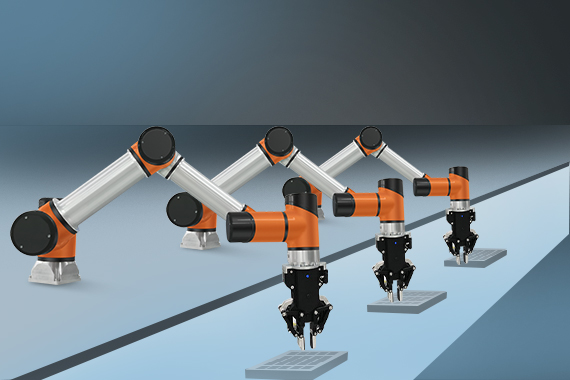

Industrial robots are automatically controlled and can be programmed on three or more axes, and they can automate various unattended processes.

Multiple industrial robots can be integrated into a fully automated production line, which means they can quickly handle applications that are not conducive to humans, thereby removing operators from unsafe or unclean environments.

Improvements in safety technology now allow industrial robots to be used for collaborative operations, providing many of the same benefits that co-robots bring, and increasing speed and accuracy.

Of course, this kind of collaboration can only be carried out after a proper risk assessment-but it is no different from choosing a co-robot.

Of course, this kind of collaboration can only be carried out after a proper risk assessment-but it is no different from choosing a co-robot.

Almost any robot can operate cooperatively under appropriate safety mechanisms.

Define cooperation

In fact, this is an application that defines the capabilities of human-machine collaboration.

In February 2016, the technical standard ISO/TS 15066 was released to provide safety guidelines for the use of robots in collaborative applications, including force guidelines, maximum allowable robot power, and speed, without discriminating against certain types of robots.

The huge growth of the co-robot market shows that co-robots can be an ideal first step towards automated processes. If the application does not require security protection, then the initial investment is low.

However, with the development of applications, multiple co-robots may soon be needed to achieve scalability, and the cost of additional equipment and labor may soon exceed that of industrial machines

Human costs and you will still lack the benefits of speed and unattended production.

Business owners must carefully evaluate the future needs of the application and its business before making a decision, and consider an important question – is a co-robot suitable for you?

This reflects the strong pressure that companies face in implementing technology to keep up or surpass the competition.

As more and more companies turn to robotic automation for success, now is the time to evaluate inventory, evaluate applications, and make smart business decisions. Without a unified solution, the automation of the manufacturing process is a complex problem.

The global co-robot market is expected to grow from US$175 million in 2016 to US$3.8 billion in 2021. This is why manufacturers really need to understand the facts before they can jump into the implementation of co-robots.

Co-robot

The original intention of the term co-robot is to represent an unattended, easy-to-integrate co-robots. These robots usually perform repetitive or unsafe tasks, while humans perform tasks upstream or downstream.

Perform higher-value manual tasks. They are very flexible, capable of performing a variety of different tasks and working side by side with humans, rather than replacing them.

Co-robots provide viable automation solutions for small and medium-sized companies because they usually have fewer upfront costs, at least at first glance.

The robotics industry does not recognize that a co-robot is a separate entity, but defines industry safety standards for humans and robots in the same production workshop.

This is an important difference, because new robot implementers may assume that any co-robot can be automatically and safely used next to humans, but in reality, this can only be determined through a comprehensive risk assessment.

If risks are not properly predicted initially, some plant managers may be surprised to find that they need expensive fences.

The result of the risk assessment is that the added safety features may cause the co-robot to run very slowly or stop multiple times.

Industrial robot

Industrial robots are automatically controlled and can be programmed on three or more axes, and they can automate various unattended processes.

Multiple industrial robots can be integrated into a fully automated production line, which means they can quickly handle applications that are not conducive to humans, thereby removing operators from unsafe or unclean environments.

Improvements in safety technology now allow industrial robots to be used for collaborative operations, providing many of the same benefits that co-robots bring, and increasing speed and accuracy.

Almost any robot can operate cooperatively under appropriate safety mechanisms.

Define cooperation

In fact, this is an application that defines the capabilities of human-machine collaboration.

In February 2016, the technical standard ISO/TS 15066 was released to provide safety guidelines for the use of robots in collaborative applications, including force guidelines, maximum allowable robot power, and speed, without discriminating against certain types of robots.

The huge growth of the co-robot market shows that co-robots can be an ideal first step towards automated processes. If the application does not require security protection, then the initial investment is low.

However, with the development of applications, multiple co-robots may soon be needed to achieve scalability, and the cost of additional equipment and labor may soon exceed that of industrial machines

Human costs and you will still lack the benefits of speed and unattended production.

Business owners must carefully evaluate the future needs of the application and its business before making a decision, and consider an important question – is a co-robot suitable for you?

Previous Article: The benefits of co-robots to manufacturing

Next Article: Analysis of China’s co-robot industry in the next few years