The difference between co-robots and traditional six-axis industrial robots

Date:2021-01-25

Co-robots are also industrial robots, but compared with traditional six-axis robots, what is the difference in technology?

In the robot application industry, traditional six-axis industrial robots are widely used in the automotive and 3C industries. These industries belong to large production enterprises. The production lines are mature and stable, and the probability of a year’s change of production is very low. Just start production directly. For applications that focus on efficiency, six-axis robots must be used. “In the promotion, it was found that many small and medium-sized enterprises, such as integrators, switch production lines very frequently. Enterprises, their demands are more frequent and easy to operate. The important point is safety. In short, traditional robots must be surrounded by safety fences. Safety accidents rarely occur, but a lot of costs are required in the safety system, and co-Robot production does not require safety fences and can be produced in collaboration with man and machine.

To sum up, the difference between the two is that the traditional six-axis industrial robot is a single species, mass production; co-robots are customized, multi-variety, and small batch production. Therefore, co-robots must meet several characteristics: easy to use, safe, and low-cost. It can independently plan graphical programming and drag teaching to reduce system integration training and programming maintenance costs; safe design reduces hardware protection investment, reduces floor space, and reduces safety investment.

To sum up, the difference between the two is that the traditional six-axis industrial robot is a single species, mass production; co-robots are customized, multi-variety, and small batch production. Therefore, co-robots must meet several characteristics: easy to use, safe, and low-cost. It can independently plan graphical programming and drag teaching to reduce system integration training and programming maintenance costs; safe design reduces hardware protection investment, reduces floor space, and reduces safety investment.

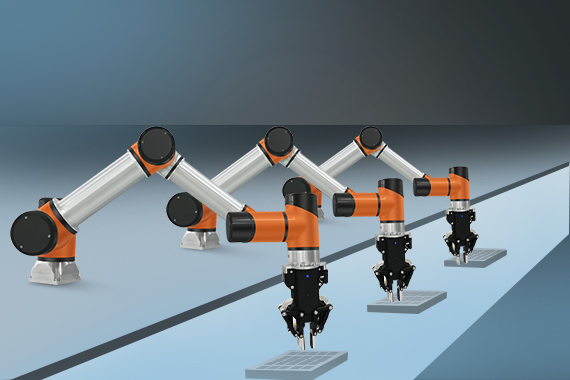

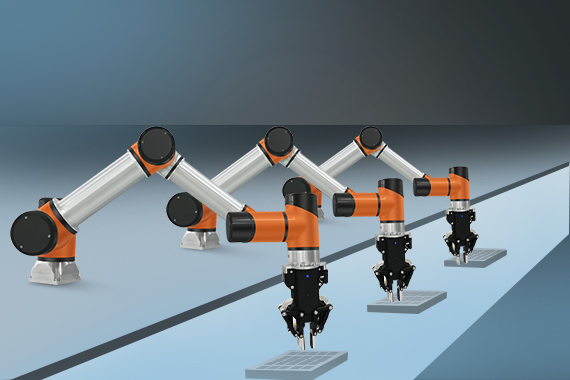

Take the automobile industry as an example. Because of their small size, high safety, flexibility, and other characteristics, co- robots have received extensive attention from automobile-related companies. The introduction of co-robots in the automobile production line can realize more intelligent production methods. Collaborative robots are mainly used in process links such as automobile locking screws, inspection, loading and unloading, grinding, and assembly.

In the robot application industry, traditional six-axis industrial robots are widely used in the automotive and 3C industries. These industries belong to large production enterprises. The production lines are mature and stable, and the probability of a year’s change of production is very low. Just start production directly. For applications that focus on efficiency, six-axis robots must be used. “In the promotion, it was found that many small and medium-sized enterprises, such as integrators, switch production lines very frequently. Enterprises, their demands are more frequent and easy to operate. The important point is safety. In short, traditional robots must be surrounded by safety fences. Safety accidents rarely occur, but a lot of costs are required in the safety system, and co-Robot production does not require safety fences and can be produced in collaboration with man and machine.

Take the automobile industry as an example. Because of their small size, high safety, flexibility, and other characteristics, co- robots have received extensive attention from automobile-related companies. The introduction of co-robots in the automobile production line can realize more intelligent production methods. Collaborative robots are mainly used in process links such as automobile locking screws, inspection, loading and unloading, grinding, and assembly.

Previous Article: 9 parameters of co-robot selection

Next Article: Co-robots--open a new era of human-machine collaboration!