How to choose the right industrial robot?

Date:2019-09-04

With the extensive application of industrial robots, more and more enterprises and factories have a better development. With the reduction of labor, many small and medium-sized enterprises have begun to choose industrial robots. But there are many kinds of industrial robots. How to choose industrial robots suitable for production? Today we will briefly talk about them.

Application occasion. Consider first what kind of situations robots are used for and what kind of processes they need. Collaborative robots are a good choice if the application process needs to be completed jointly by human and machine, especially in the case of changing work station or shifting line frequently and cooperating with a new type of torque sensor.

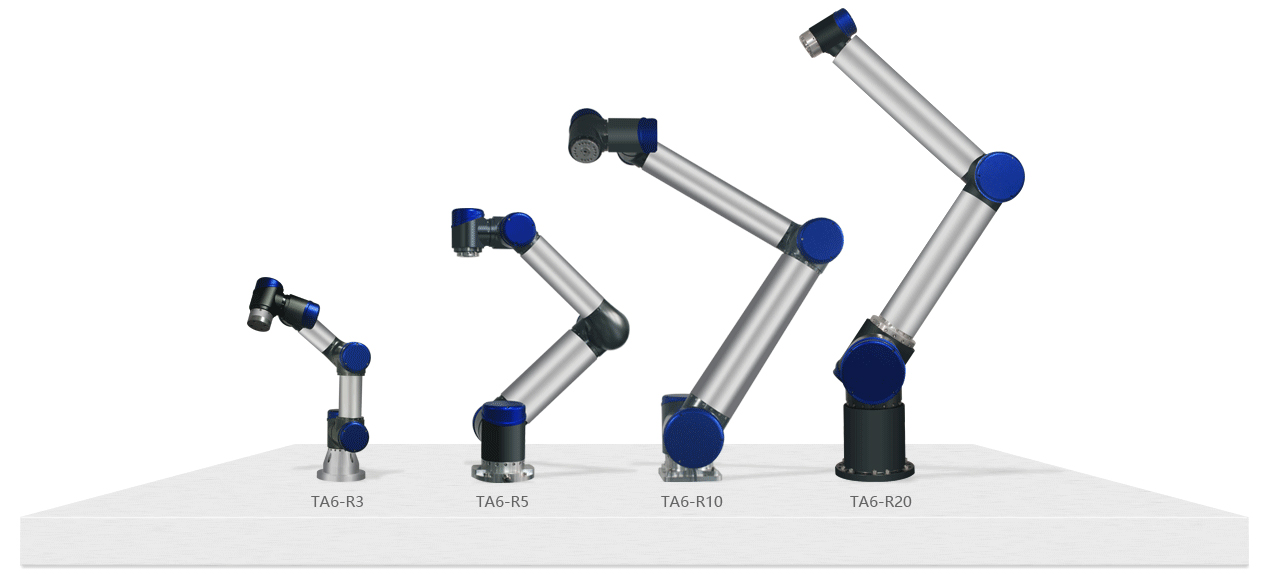

Payload. It refers to the maximum load that a robot can carry in the workspace. If the robot completes the task of moving the target workpiece from one station to another, we need to pay attention to add the weight of the workpiece and the weight of the robot's gripper to its workload. In particular, it should be noted that the load curve of the robot, at different distances in the space range, actually has different load capacity.

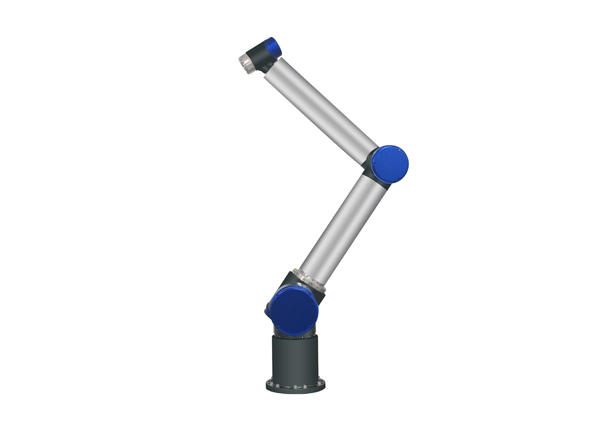

Degree of freedom (number of axes). The number of axes allocated by the robot is directly related to the degree of freedom of the robot in motion. If it's for a simple straight-up situation, the 4-axis robot can deal with it. If it is used in a narrow workspace and requires a lot of twisting and rotation of the robot arm, 6-axis or 7-axis robots are the best choice.

Maximum range of action. When using computer robots, we should also know the maximum distance that robots need to reach. Choosing a robot depends not only on its payload, but also on the exact distance it can reach. In this way, it can be judged whether the industrial robot is suitable for specific applications. In the horizontal motion range of the robot, we should also pay attention to the non-working areas of the robot's close body and rear.

Application occasion. Consider first what kind of situations robots are used for and what kind of processes they need. Collaborative robots are a good choice if the application process needs to be completed jointly by human and machine, especially in the case of changing work station or shifting line frequently and cooperating with a new type of torque sensor.

Payload. It refers to the maximum load that a robot can carry in the workspace. If the robot completes the task of moving the target workpiece from one station to another, we need to pay attention to add the weight of the workpiece and the weight of the robot's gripper to its workload. In particular, it should be noted that the load curve of the robot, at different distances in the space range, actually has different load capacity.

Degree of freedom (number of axes). The number of axes allocated by the robot is directly related to the degree of freedom of the robot in motion. If it's for a simple straight-up situation, the 4-axis robot can deal with it. If it is used in a narrow workspace and requires a lot of twisting and rotation of the robot arm, 6-axis or 7-axis robots are the best choice.

Maximum range of action. When using computer robots, we should also know the maximum distance that robots need to reach. Choosing a robot depends not only on its payload, but also on the exact distance it can reach. In this way, it can be judged whether the industrial robot is suitable for specific applications. In the horizontal motion range of the robot, we should also pay attention to the non-working areas of the robot's close body and rear.

Previous Article: Development Status of GBA Robot Ecology

Next Article: Reasons for the Difficulty of Popularizing Industrial Robots in China