Reasons for the Difficulty of Popularizing Industrial Robots in China

Date:2019-08-27

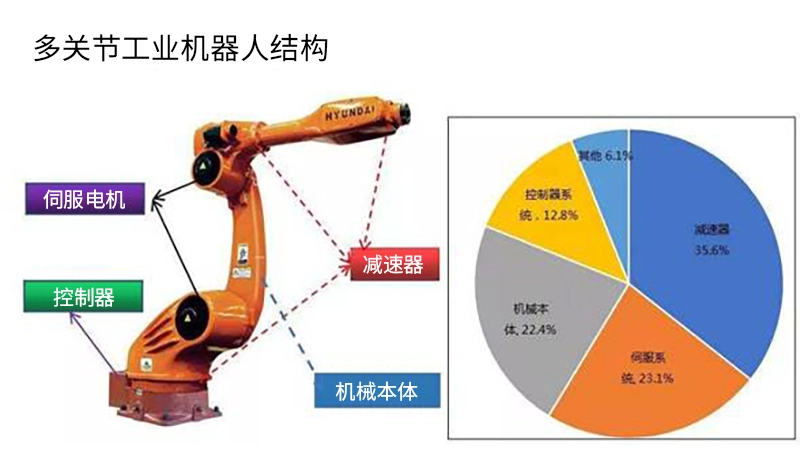

Sometimes many people may have a misunderstanding that industrial robots and intelligent robots are a concept, both of which are robots with high degree of intelligence. Of course, they think the two concepts are the same. In fact, industrial robots and intelligent robots are two completely different concepts. Industrial manipulators can be understood as industrial robots. Intelligent robot is an ideal research platform of artificial intelligence, and it is a machine system that simulates human beings comprehensively in perception, thinking and effect. At present, the technology of industrial robots is progressing continuously. At the same time, more and more young people choose to engage in research projects of industrial robotics technology, and devote themselves to developing China's industrial robotics technology to become the world's leader!

Introduce the types of industrial robots for you:

1. Operational industrial robots: They can be automatically controlled, reprogrammed, and have multiple degrees of freedom. They can be used in related automation systems.

2. Programmable industrial robots: According to the required sequence and conditions, the mechanical action of the robots is controlled.

3. Teaching and Reproducing Industrial Robot: First teach the robot action, input the working procedure, and let it repeat its work automatically.

4. NC Industrial Robot: It teaches the robot by numerical value and language, and the robot works according to the information after teaching.

5. Sensory Control Industrial Robot: Use the information acquired by sensors to control the action of the robot.

6. Adaptive Control Industrial Robot: It can adapt to environmental changes and control its own actions.

7. Learning Control Industrial Robot: It has a certain learning function and can apply the learning experience to work.

With a general understanding of industrial robotics technology, let's think about this: in Chinese factories, industrial robots are relatively rarely used?

Industrial robots are so popular, why only a few large factories in China have applied industrial robots?

1. The cost is too high to popularize.

Industrial robots still belong to precision devices, which need high technology level, large investment in research and development, and high cost of industrial robots produced. Usually, it is difficult for factories to deploy industrial robots and the investment is too large in the early stage, which requires funds to continue maintenance in the later stage.

2. Different production needs of factories

Each factory has its own production process, which requires different customization of industrial robots. The cost of investment is high and maintenance is difficult. For large manufacturing enterprises, it is indeed possible to improve efficiency, increase product accuracy and improve product yield. But for small and medium-sized enterprises, it is not necessary.

3. Cost trading control for workers compared with industrial robots

Staff members have mobility, more orders, and when business is good, more workers can be recruited to carry out production. If there are fewer orders, fewer people can be recruited, which can maintain the saturation of factory production and adjust the input of production cost dynamically. Industrial robots are different. Whether your business is good or bad, industrial robots need to continue to invest in costs.

4. Industrial robots are still unable to replace workers on a large scale.

In the production process, many actions or operations still need human thinking. When it comes to thinking ability, it is difficult for robots to replace it at present. Although industrial robots are developing towards artificial intelligence, they also have certain learning ability. But at present, it can only completely replace some repetitive operators.

Even though artificial intelligence robots and industrial robots are developing so rapidly, they can not replace workers in many practical application scenarios. For small and medium-sized factories, the high cost of investment is unable to cross the threshold. At present, many factories prefer to move their factories to some developed countries to reduce production costs, and there is no widespread industrial robots.

However, with the development of industrial robotics technology, industrial robots will eventually take the place of some people's work. If industrial robots take the place of human beings to do some heavy processes, then workers will liberate more labor and do something more valuable.

Introduce the types of industrial robots for you:

1. Operational industrial robots: They can be automatically controlled, reprogrammed, and have multiple degrees of freedom. They can be used in related automation systems.

2. Programmable industrial robots: According to the required sequence and conditions, the mechanical action of the robots is controlled.

3. Teaching and Reproducing Industrial Robot: First teach the robot action, input the working procedure, and let it repeat its work automatically.

4. NC Industrial Robot: It teaches the robot by numerical value and language, and the robot works according to the information after teaching.

5. Sensory Control Industrial Robot: Use the information acquired by sensors to control the action of the robot.

6. Adaptive Control Industrial Robot: It can adapt to environmental changes and control its own actions.

7. Learning Control Industrial Robot: It has a certain learning function and can apply the learning experience to work.

With a general understanding of industrial robotics technology, let's think about this: in Chinese factories, industrial robots are relatively rarely used?

Industrial robots are so popular, why only a few large factories in China have applied industrial robots?

1. The cost is too high to popularize.

Industrial robots still belong to precision devices, which need high technology level, large investment in research and development, and high cost of industrial robots produced. Usually, it is difficult for factories to deploy industrial robots and the investment is too large in the early stage, which requires funds to continue maintenance in the later stage.

2. Different production needs of factories

Each factory has its own production process, which requires different customization of industrial robots. The cost of investment is high and maintenance is difficult. For large manufacturing enterprises, it is indeed possible to improve efficiency, increase product accuracy and improve product yield. But for small and medium-sized enterprises, it is not necessary.

3. Cost trading control for workers compared with industrial robots

Staff members have mobility, more orders, and when business is good, more workers can be recruited to carry out production. If there are fewer orders, fewer people can be recruited, which can maintain the saturation of factory production and adjust the input of production cost dynamically. Industrial robots are different. Whether your business is good or bad, industrial robots need to continue to invest in costs.

4. Industrial robots are still unable to replace workers on a large scale.

In the production process, many actions or operations still need human thinking. When it comes to thinking ability, it is difficult for robots to replace it at present. Although industrial robots are developing towards artificial intelligence, they also have certain learning ability. But at present, it can only completely replace some repetitive operators.

Even though artificial intelligence robots and industrial robots are developing so rapidly, they can not replace workers in many practical application scenarios. For small and medium-sized factories, the high cost of investment is unable to cross the threshold. At present, many factories prefer to move their factories to some developed countries to reduce production costs, and there is no widespread industrial robots.

However, with the development of industrial robotics technology, industrial robots will eventually take the place of some people's work. If industrial robots take the place of human beings to do some heavy processes, then workers will liberate more labor and do something more valuable.

Previous Article: How to choose the right industrial robot?

Next Article: 2019 World Robot Congress opens in Beijing