Robot Actuators: Types, Design, Operation, and Applications

Date:2025-07-21Robots are advanced electromechanical systems capable of performing diverse tasks by sensing their environment and executing actions. A critical component in robotics, actuators enable precise movement and functionality.

What is a Robot Actuator?

A robot actuator converts energy into physical motion, driving joint rotation, wheel movement, or gripper operation in robots. Available in various types based on load requirements—such as torque, precision, speed, and power consumption—actuators typically produce linear or rotational motion.

Common Types of Robot Actuators

Rotational Motion Actuators:

These actuators control and monitor rotational movement in robotic components. Available in various sizes with adjustable torque, they enable speed regulation and controlled pauses, ideal for joint operations in robots.

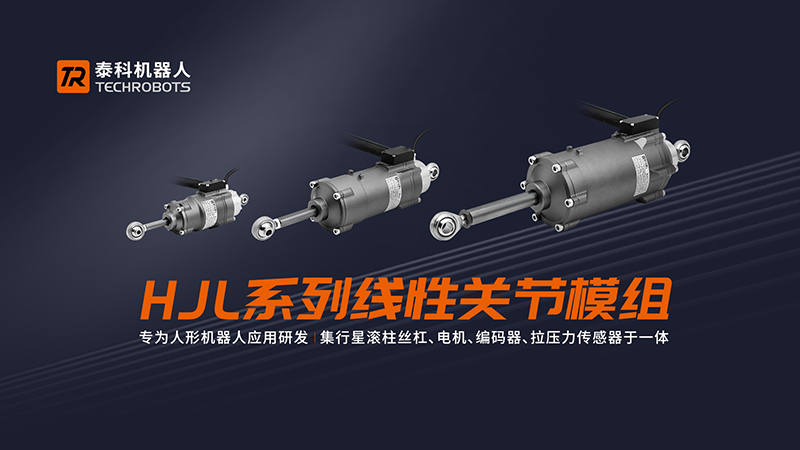

Linear Motion Actuators:

Linear actuators facilitate push or pull motions, such as forward/backward movement or arm extension. Connected to a robot’s lever arm, they are widely used across robotics applications.

Robot Actuator Design

Actuators come in diverse forms. This section focuses on designing linear actuators that convert rotational motion into push/pull linear motion, delivering safe, efficient motion control.

• Power:

The primary design consideration is power. Mechanical output depends on input power, determined by the load or force required.

• Duty Cycle:

This refers to the actuator’s operational frequency and duration, influenced by heat loss during motion. Duty cycles vary based on load, aging, and ambient temperature.

• Efficiency:

Efficiency is calculated as the ratio of mechanical output to electrical input, reflecting operational performance.

• Lifespan:

Extending actuator life involves maintaining rated duty cycles, minimizing side loads, adhering to recommended voltage and force, and avoiding extreme environments.

Operating Principle

Robot actuators are designed for ease of use and efficiency. Linear actuators, for instance, utilize threaded roller screws to create force over a distance, enabling push/pull motion for precise load movement.

Key Considerations for Selecting Robot Actuators

• Purpose and Functionality:

The actuator type depends on the robot’s intended function.

• Physical Constraints:

Weight and size are critical, as oversized actuators may compromise small robotic arms.

• Strength and Power:

Actuators must have sufficient strength and power for specific tasks.

• Communication Protocols:

Verify that the actuator supports industry-standard communication protocols, such as EtherCAT or CANopen, widely used in robotics.

• Mounting Options:

Verify available mounting space and actuator-specific hardware, which may support multi-orientation installation or custom fixed points.

Advantages of Robot Actuators

• High precision

• Easy to control

• High energy conversion efficiency

• Safe and simple operation

• Low maintenance

• Cost-effective

Applications of Robot Actuators

• Convert external energy into physical motion based on control signals.

• Transform electrical energy into linear or rotational motion.

• Generate forces for robots to move themselves or other objects.

• Control and drive robotic systems or mechanisms.

Conclusion

Actuators are vital to robotics, enabling precise joint and limb movements by converting energy into mechanical motion. They are essential for achieving accurate, multi-directional robot operations.