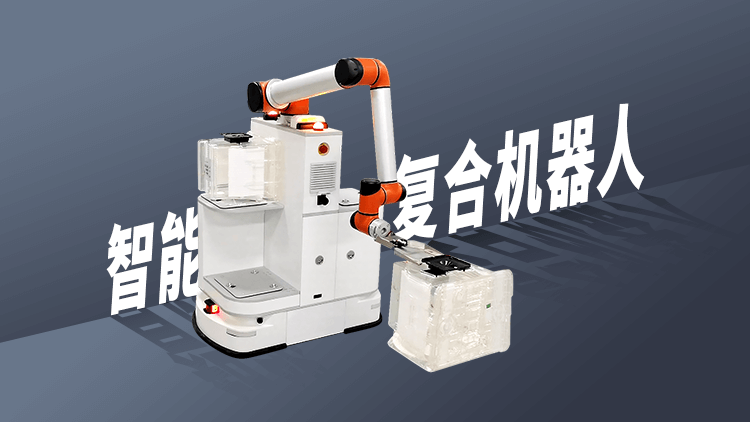

Compound robots: The next generation of industrial robots.

Date:2023-04-14Compound robots, also known as collaborative robots, represent a new generation of robots that combine various types to integrate capabilities such as "hands, feet, eyes, and brains." They exhibit higher intelligence and flexibility, enabling precise and complex task operations.

Compared to traditional robots, compound robots employ advanced sensors and control systems for accurate perception of the surrounding environment and collaboration with humans. They adapt to diverse task requirements by combining different robot modules, allowing modular assembly and disassembly based on varying work environments and tasks. This flexibility enhances the robot's efficiency and scalability. Currently, compound robots composed of integrated mobile and collaborative robots find widespread application in automation. Furthermore, they leverage technologies like the internet and cloud computing for remote operation and intelligent management, enhancing task efficiency. Major global robot manufacturers, including Chinese enterprises, actively contribute to the research and application of compound robots. They develop multifunctional compound robots tailored for different industries, boosting the robots' utility and applicability.

Compound robots represent a vital direction in robot technology, propelling continuous advancements and expanding application scopes. With ongoing innovation and development, compound robots are progressively perfected, anticipating broader applications. By integrating different types of robots into a unified system, they offer flexible and diverse functionalities, significantly broadening the range and efficacy of robotic applications.

1. Technical Principles of Compound Robots:

Compound robots incorporate advanced technologies such as machine vision, machine learning, and adaptive control. Machine vision enables the robot to perceive and recognize the surrounding environment, including object shapes, colors, and positions. Machine learning allows the robot to autonomously learn and adapt to tasks, continually improving efficiency and accuracy. Adaptive control enables the robot to autonomously adjust control parameters based on task and environmental changes to ensure effective task completion.

2.Application Scenarios of Compound Robots:

Compound robots find applications across various industrial sectors, including automotive manufacturing, electronics manufacturing, food processing, and pharmaceutical production. In automotive manufacturing, they collaborate with workers to perform tasks like body welding and component assembly, enhancing production efficiency and product quality. In electronics manufacturing, compound robots automate the production and testing of circuit boards, reducing production costs and defect rates. In food processing and pharmaceutical production, they handle tasks such as food packaging and drug assembly to ensure product hygiene and safety.

3. Future Development Prospects of Compound Robots:

Compound robots, as a new type of industrial robot, have broad development prospects. In the future, they will become a mainstay in industrial automation, widely applied in industrial production, logistics, and service fields. With the continuous development of artificial intelligence and machine learning technologies, compound robots will enhance their levels of intelligence and autonomy, enabling broader applications and more efficient task collaboration.

4. Challenges and Solutions for Compound Robots:

Despite the vast application prospects, compound robots face challenges, with safety being a primary concern due to their collaboration with humans. Strengthening safety measures in the design and application of compound robots is crucial to ensuring safe collaboration with humans. Additionally, technical integration poses a challenge, requiring effective integration and fusion of various technologies, including machine vision, machine learning, and adaptive control. Advanced technology integration methods and processes are necessary to ensure synergy and integration of technologies in compound robot design and manufacturing.

5. Future Development Directions of Compound Robots:

As compound robots continue to evolve and find applications, their future development directions become clearer. There is a need to further enhance the intelligence and autonomy of compound robots for more efficient task collaboration and autonomous decision-making. Developing more application scenarios and use cases to meet the diverse needs of different industrial sectors is essential. Strengthening safety measures and technical integration for compound robots is necessary to ensure their safety and effectiveness in applications.

In summary, compound robots represent a new type of industrial robot with vast application prospects, capable of collaborating on more complex tasks. They inject new energy and vitality into the development of industrial automation. As artificial intelligence and machine learning technologies continue to advance, the intelligence and autonomy of compound robots will continually improve. In the future, they will become a mainstay in industrial automation, bringing more convenience and benefits to humanity.

Previous Article: Application Scenarios of Dual-Arm Collaborative Robots

Next Article: Collaborative Robot Application Scenarios in 2023