2023 Collaborative Robot Trends: Strong Momentum in the Chinese Market

Date:2023-03-15

As automation technology advances and becomes widely adopted, the use of robots has grown at an astonishing rate, reaching record highs in annual installations. The robotics industry has become a crucial pillar of the global economy, with China emerging as the largest and fastest-growing market for robots. In recent years, China's emphasis on intelligent manufacturing has led to rapid development in the automation market. In 2023, the Chinese collaborative robot market is expected to maintain strong momentum, with flexibility, high payload capacity, versatility across all scenarios, and customer collaboration becoming essential for industry development.

一、Strong Momentum in the Collaborative Robot Market

Collaborative robots, as a rapidly developing product type in the industrial robot field, not only possess advantages of "safety, flexibility, and ease of use" but also demonstrate a significant price advantage, aligning perfectly with the manufacturing industry's desire for "cost reduction and efficiency improvement." Simultaneously, propelled by various policies such as the "Robot+" Application Action Plan, China, as the world's largest manufacturing industry, will experience a rapid increase in collaborative robot installations, doubling the installed base. Terminal recognition of collaborative robots is accelerating, and it is expected that from 2023 to 2025, the average growth rate of collaborative robot shipments in China will remain around 37%, entering a phase of rapid development.

Behind the substantial demand for robots is not only the market's extreme requirements for efficiency but also the widespread labor shortage problem faced by the global manufacturing industry, including China. The difficulty in recruiting workers is particularly evident in general labor positions, as low-paying repetitive work lacks appeal and a sense of accomplishment for young people. The Ministry of Human Resources and Social Security's ranking of the "100 Most In-Demand Occupations" for the third quarter of 2022 included a staggering 39 positions related to production and manufacturing personnel. Simultaneously, the labor shortage is also evident in the gap for high-skilled talent. Automation methods, while replacing basic tasks, have also created many new positions, catalyzing demand for high-skilled talent. In recent years, the job-to-applicant ratio for high-skilled talent in China has consistently remained above 2, indicating a high demand, with one technical skill professional corresponding to at least two positions.

The use of safe, flexible, and convenient collaborative robots to replace tedious, dangerous, repetitive, and labor-intensive tasks allows workers to focus on more valuable work. This not only improves production efficiency but also enhances employee satisfaction and a sense of accomplishment.

Behind the substantial demand for robots is not only the market's extreme requirements for efficiency but also the widespread labor shortage problem faced by the global manufacturing industry, including China. The difficulty in recruiting workers is particularly evident in general labor positions, as low-paying repetitive work lacks appeal and a sense of accomplishment for young people. The Ministry of Human Resources and Social Security's ranking of the "100 Most In-Demand Occupations" for the third quarter of 2022 included a staggering 39 positions related to production and manufacturing personnel. Simultaneously, the labor shortage is also evident in the gap for high-skilled talent. Automation methods, while replacing basic tasks, have also created many new positions, catalyzing demand for high-skilled talent. In recent years, the job-to-applicant ratio for high-skilled talent in China has consistently remained above 2, indicating a high demand, with one technical skill professional corresponding to at least two positions.

The use of safe, flexible, and convenient collaborative robots to replace tedious, dangerous, repetitive, and labor-intensive tasks allows workers to focus on more valuable work. This not only improves production efficiency but also enhances employee satisfaction and a sense of accomplishment.

二、Flexible and Rapid Enhancement Meets the Varied Needs of Flexible Manufacturing

In an environment where the importance of resilience in the manufacturing industry supply chain has been magnified, global manufacturing enterprises urgently need to enhance production flexibility and lean management through digitalization and automation to achieve agile production. In addition to the global macro environment, the ever-changing demands of end consumers in the digital age also pose another pressure on enterprise production, forcing companies to "produce to demand" and agilely respond to market needs. The traditional labor model cannot keep up with the fast pace of flexible production, requiring enterprises to comprehensively upgrade factory systems through automation. In the process of embracing automation, traditional industrial robots, due to their lack of flexibility and difficulty in deployment, limit their application scenarios. To better adapt to the requirements of flexibility, speed, and easy deployment, more and more enterprises are turning to collaborative robots.

Unlike traditional industrial robots, collaborative robots can directly interact with employees at close range, matching existing workstations and workstations without the need for additional safety barriers or changes to the existing factory layout. The installation and operation of collaborative robots are also very convenient, allowing for flexible and rapid redeployment and task switching across multiple production line processes. Even operators without programming experience can quickly set up and operate collaborative robots through an intuitive and user-friendly interface with minimal training.

Unlike traditional industrial robots, collaborative robots can directly interact with employees at close range, matching existing workstations and workstations without the need for additional safety barriers or changes to the existing factory layout. The installation and operation of collaborative robots are also very convenient, allowing for flexible and rapid redeployment and task switching across multiple production line processes. Even operators without programming experience can quickly set up and operate collaborative robots through an intuitive and user-friendly interface with minimal training.

三、Collaborative Robots Achieve New Heights in Payload and Accuracy

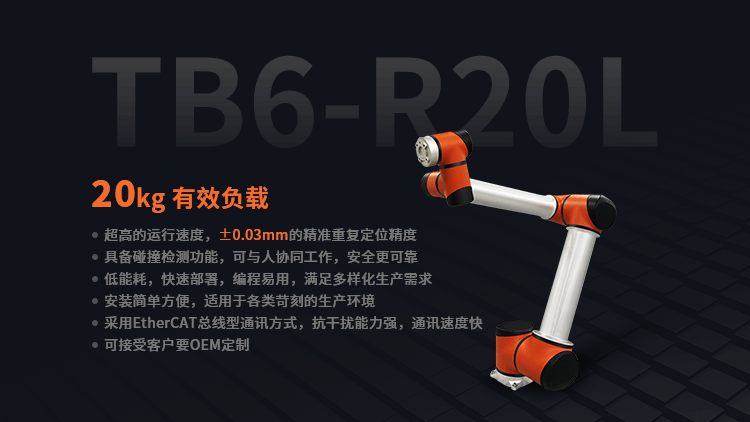

In the past, collaborative robots were primarily used by customers for tasks with low payload requirements due to their flexible and lightweight characteristics. However, in recent years, more and more enterprises wish to use collaborative robots in areas with higher payload requirements, replacing tasks previously handled by traditional industrial robots. In response to the market's urgent demand for high payload robots, Shenzhen Taike Intelligent Robot's TB6-R20L collaborative robot has achieved comprehensive breakthroughs in payload capacity, operating range, and more. It can handle a large payload of 20kg and a working radius of 1500mm, with a high repeatability positioning accuracy of up to ±0.03mm. This redefines collaborative robots and has successfully customized a collaborative robot with a payload of 30kg for customers.

四、One-Stop Customized Solutions Empower Chinese Manufacturing

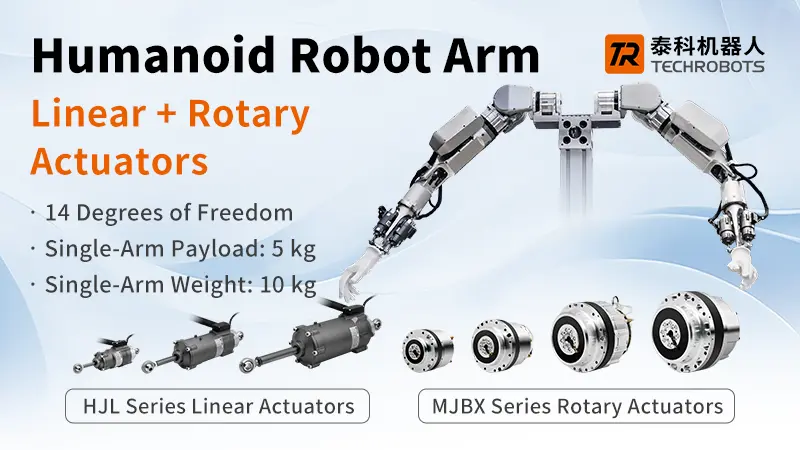

Despite the rapid development of technology in recent years, bringing revolutionary changes to various industries, a basic fact remains: no technology company can excel in everything. The robotics industry is no exception, as the development of robotic systems involves hardware, software, applications, sensors, and interfaces, requiring the power of an ecosystem to easily expand functionalities for various scenarios. Taike Intelligent has consistently adhered to independent research and development, pursuing excellence and placing customer unique needs at the center. They provide a one-stop OEM customized, efficient, and competitive robotic solution, empowering Chinese manufacturing. The product series include collaborative robots, robot joint modules, robot motors, servo drives, brakes, incremental/absolute encoders, and more, widely applied in factory automation, automotive, 3C (computer, communication, consumer electronics), medical, power, research, education, inspection, and other application fields.

五、Customers Play a Vital Role in the Product Development Process

Customers understand their needs better than anyone else. As the market matures, today's customers are more capable than ever of providing valuable feedback and suggestions for product development. Taike Intelligent Robots consistently innovates and iterates based on real customer feedback, continuously improving the level of customized service and accurately understanding customer needs. From standard to customized solutions, Taike Intelligent Robots helps customers shorten the robot design and development cycle, providing you with an efficient and competitive collaborative robot solution tailored to your needs. They solve problems for you, unleash maximum value, open up new possibilities, and help you achieve your business goals.