Robotics trends: co-robots, agricultural robots and medical robots

Date:2020-08-07

From leisure robots such as drones to key operational robots in the medical field, robotics is changing our daily lives. Stewart Goulding, managing director of Electro-Mechanical Systems Ltd, a supplier of precision drive systems, explored some of the current trends in the industry here. More information is available in the vibration industry chain.

Robots are everywhere-from robotic wearables, hands, and arms to companion robots, medical equipment, and even biomorphic drones that mimic the behavior of bees. The main developments in the industry include co-robots, drones, and medical robots.

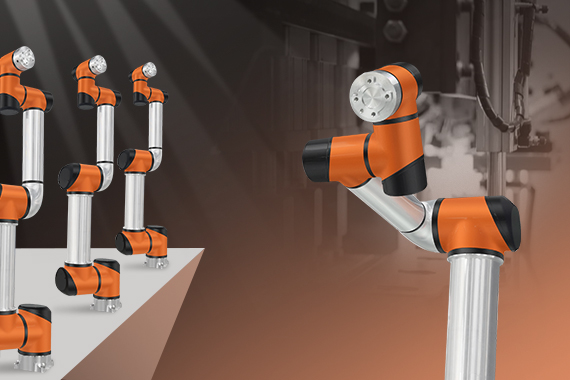

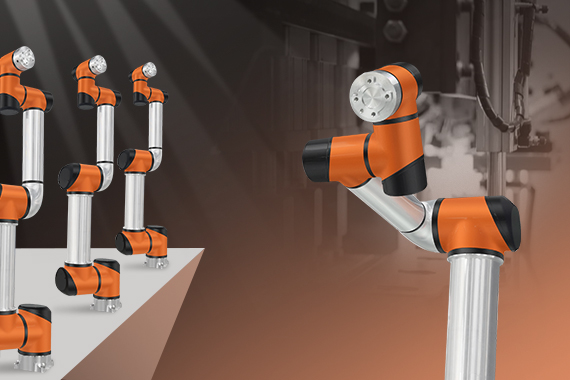

Co-robots in the workplace

Since its introduction in the mid-2010s, co-robots or co-robots have taken the market by storm. Co-robots provide various opportunities for the production line, especially to enable humans and robots to complement each other and at the same time safely cooperate. The new trend for these types of robots is to make them easier to use, and now have more cost-effective options that enable greater distribution and use.

However, this is not a single way for robots to collaborate with production line workers. The exoskeleton is a kind of mechanical equipment that can help workers move at a uniform speed, provide support for workers when lifting heavy objects, and provide portable seats to help prevent workers from being stressed.

These applications can not only increase the strength of the production line, but also reduce the labor pressure, and with the popularization of co-robots, exoskeletons, and future forms, they will bring more obvious benefits to workers, production processes and enterprises.

Co-robots can reduce human production input by up to 50%. The current skills gap has cost British organizations billions of dollars to integrate co-robots and other robotic applications, which may have a positive impact on the economy.

Medical robot

In recent years, the focus has been on revolutionizing non-invasive and minimally invasive surgery. As a result, a large number of new surgical robots are ready. For example, i-Snake® and Micro-IGES are both precisions robotic alternatives to traditional surgery.

Due to more accurate diagnostic methods, the number of non-invasive and minimally invasive procedures has skyrocketed. This puts physical and organizational pressure on surgeons who perform these procedures. Therefore, robot alternatives provide advantages for public health services.

Therefore, these robots must be as accurate and reliable as possible to ensure that they can help reduce pressure on the medical system. For example, endoscopy is a minimally invasive procedure that allows doctors to examine the inside of a patient, a procedure supported by robot development.

Endoscopic robots must be compact and consistently accurate. Therefore, when the French company EndoControl developed its new endoscope Viky system, it chose a series of FAULHABER brushless DC motors, which helped achieve the required accuracy and consistency.

These motors are equipped with a free reducer, and a variety of reduction ratios can be selected from about 3:1 to 1500:1 so that the speed and torque of the equipment can be widely adjusted. Using the FAULHABER drive system, a precise movement of 700 mNm can be achieved in the very system.

These types of developments are essential to ensure that medical institutions can cope with the increasing number of surgical operations while reducing fatigue, keeping surgeons healthy, and avoiding burnout.

Agricultural robot

No wonder there are more agricultural robot applications, including biomorphic drones that mimic the behavior of bees. Robots and drones can have a significant impact on farming efficiency. From drones that monitor and analyze crops to automatic tractors that can sow, fertilize, and harvest, the development of agricultural robots means that people can now usually invest in more complex tasks.

These applications require precise actuation to increase the efficiency of the system. The drone camera needs a smooth tilt and pan movement to ensure that accurate and usable images are taken to help you. FAULHABER iron-free rotor DC motors are widely used in mobile camera applications, including defense reconnaissance and film or television filming because they allow precise cogging free movement to capture important information.

Therefore, cameras used in agricultural drones and other agricultural monitoring systems are a natural extension of this motor. Although drones may be considered leisure toys, their ability to autonomously cover and observe large areas of land in a short period while consuming less fuel is of great benefit to reducing operating costs.

Some rural farms in China have begun to use heavy industrial drones to water crops in hard-to-reach areas. Facts have proved that this method is more fuel-efficient than transportation workers, and the computer-controlled sprayer wastes fewer resources.

Therefore, whether it is across the production line, in the surgical operating room, or the broad agricultural field, robotic applications can provide all relevant personnel with innovative and reliable working methods. More information is available in the vibration industry chain.

Robots are everywhere-from robotic wearables, hands, and arms to companion robots, medical equipment, and even biomorphic drones that mimic the behavior of bees. The main developments in the industry include co-robots, drones, and medical robots.

Co-robots in the workplace

Since its introduction in the mid-2010s, co-robots or co-robots have taken the market by storm. Co-robots provide various opportunities for the production line, especially to enable humans and robots to complement each other and at the same time safely cooperate. The new trend for these types of robots is to make them easier to use, and now have more cost-effective options that enable greater distribution and use.

However, this is not a single way for robots to collaborate with production line workers. The exoskeleton is a kind of mechanical equipment that can help workers move at a uniform speed, provide support for workers when lifting heavy objects, and provide portable seats to help prevent workers from being stressed.

These applications can not only increase the strength of the production line, but also reduce the labor pressure, and with the popularization of co-robots, exoskeletons, and future forms, they will bring more obvious benefits to workers, production processes and enterprises.

Co-robots can reduce human production input by up to 50%. The current skills gap has cost British organizations billions of dollars to integrate co-robots and other robotic applications, which may have a positive impact on the economy.

Medical robot

In recent years, the focus has been on revolutionizing non-invasive and minimally invasive surgery. As a result, a large number of new surgical robots are ready. For example, i-Snake® and Micro-IGES are both precisions robotic alternatives to traditional surgery.

Due to more accurate diagnostic methods, the number of non-invasive and minimally invasive procedures has skyrocketed. This puts physical and organizational pressure on surgeons who perform these procedures. Therefore, robot alternatives provide advantages for public health services.

Therefore, these robots must be as accurate and reliable as possible to ensure that they can help reduce pressure on the medical system. For example, endoscopy is a minimally invasive procedure that allows doctors to examine the inside of a patient, a procedure supported by robot development.

Endoscopic robots must be compact and consistently accurate. Therefore, when the French company EndoControl developed its new endoscope Viky system, it chose a series of FAULHABER brushless DC motors, which helped achieve the required accuracy and consistency.

These motors are equipped with a free reducer, and a variety of reduction ratios can be selected from about 3:1 to 1500:1 so that the speed and torque of the equipment can be widely adjusted. Using the FAULHABER drive system, a precise movement of 700 mNm can be achieved in the very system.

These types of developments are essential to ensure that medical institutions can cope with the increasing number of surgical operations while reducing fatigue, keeping surgeons healthy, and avoiding burnout.

Agricultural robot

No wonder there are more agricultural robot applications, including biomorphic drones that mimic the behavior of bees. Robots and drones can have a significant impact on farming efficiency. From drones that monitor and analyze crops to automatic tractors that can sow, fertilize, and harvest, the development of agricultural robots means that people can now usually invest in more complex tasks.

These applications require precise actuation to increase the efficiency of the system. The drone camera needs a smooth tilt and pan movement to ensure that accurate and usable images are taken to help you. FAULHABER iron-free rotor DC motors are widely used in mobile camera applications, including defense reconnaissance and film or television filming because they allow precise cogging free movement to capture important information.

Therefore, cameras used in agricultural drones and other agricultural monitoring systems are a natural extension of this motor. Although drones may be considered leisure toys, their ability to autonomously cover and observe large areas of land in a short period while consuming less fuel is of great benefit to reducing operating costs.

Some rural farms in China have begun to use heavy industrial drones to water crops in hard-to-reach areas. Facts have proved that this method is more fuel-efficient than transportation workers, and the computer-controlled sprayer wastes fewer resources.

Therefore, whether it is across the production line, in the surgical operating room, or the broad agricultural field, robotic applications can provide all relevant personnel with innovative and reliable working methods. More information is available in the vibration industry chain.