Co-robot multi-scenario application case

Date:2020-07-24

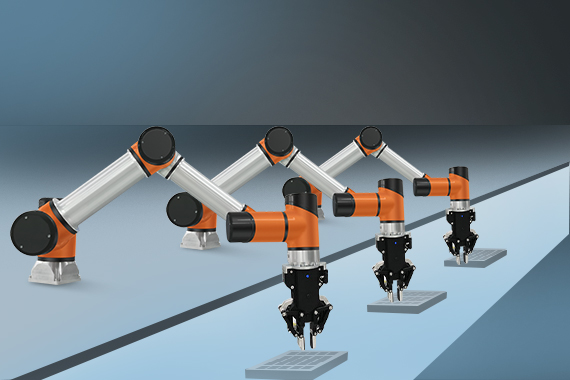

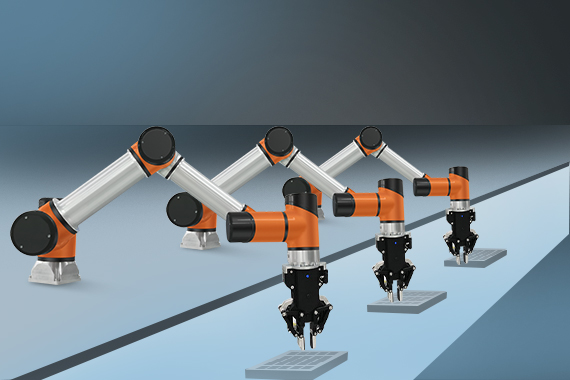

Co-robots are a very flexible tool that can perform similar actions like human arms, but they have a wider range of applications. They will not feel tired, and can perform dangerous tasks without being hurt.

Based on the characteristics of human-to-human collaboration, high safety, low cost, flexibility and ease of use, the collaborative machine greatly meets the high requirements of enterprises for flexible production.

Demonstration application case:

Demonstration application case:

1.3C scenario

As the world's largest 3C production base, the potential demand for robots in the 3C industry will reach 1 million in the future. Compared with Japan and South Korea, which have 1,200 3C industrial robots per 10,000 people, the number of robots in China's 3C industry is almost negligible. Some parts are automatically processed, and most of them are manufactured manually.

However, China’s industrial agglomeration and integration schemes are easy to standardize; the density of robots is the lowest and the room for growth is large; the competition of foundries is fierce and the demand is strong. Various good factors indicate that due to the explosive growth of the demand for robots in the 3C industry, the robot industry will be very The next industry explosion is coming soon.

Taking the mobile phone industry as an example, the requirements for mobile phone products are getting higher and higher and facing many challenges:

1. The parts are small in size, and most of the parts are millimeter-level;

2. Irregular parts, irregular parts (camera, cable, etc.);

3. There are many product styles and many product series;

4. The update cycle is fast, and a special device may not be suitable for new products after only a few months;

5. High appearance requirements, no slight scratches on the surface;

6. High-speed requirements, production efficiency is very important for mobile phone manufacturing;

7. The failure rate is low, and the failure will cause the whole line to stop production.

8. There is a shortage of skilled workers in the production line, a shortage of skilled workers, and unskilled skills;

9. Quality control is difficult, and production efficiency control is uncertain;

10. Labor wages are rising rapidly, and failures will cause the entire line to stop production;

11. Factors such as workers' emotionality, repetitive work, and sabotage will affect the production of products.

The six-axis and seven-axis co-robots developed and produced by Techrobots have certain advantages in certain applications. They can not only meet the automatic conversion of existing production lines in small spaces but are also very suitable for this labor-intensive industry." The need for man-machine collaboration.

They can automate many different applications.

They are small in size and light in weight and can be easily transferred to different processes in the workshop.

They are easy to program, and users can save programs for reuse.

2. Car scene

At present, many automobile companies are looking for solutions to increase the labor intensity of the production line, in order to increase the degree of production automation, increase production capacity, and thus bring added value to the production process. In today's Industry 4.0, automation solutions are not only the pursuit of mechanization, but also a new automation solution that pays more attention to safety, flexibility, and movement anytime and anywhere when needed, and also needs to achieve higher security To speed up the return on investment.

In order to fill the gaps in workers and improve production quality, Techrobots smart robots can tighten the engine block by tightening the end of the module, as well as an automatic screw supply system.

In the process of tightening the robot with the tightening gun, the screw automatic feed system controls the nail speed and reminds the lack of material through the control unit, the tightening module detects the position of the screw through the screw position sensor, and the electric CNC screwdriver uses the depth sensor to detect and torque monitor feedback If the screw is tightened, the robot can carry the tightening module to achieve multi-position and fast tightening work.

During the tightening process, the maximum torque that different co-robots can achieve is affected by the speed reducer used by the robot and the expansion of the arm. During the tightening process, the maximum torque that different co-robots can achieve is affected by the speed reducer used by the robot and the expansion of the arm.

The arm span of the Techrobots TB6 series of co-robots ranges from 666 mm to 1500 mm, which can basically meet the torque requirements of different tightening situations. Among them, the TB6-R3 co-robot, small and light robots can meet the requirements of small space tightening. TB6 -The R20 co-robot can be applied to various large-load and long-arm display work areas due to its excellent high torque output performance and the development of a 1500 mm long arm.

The arm span of the Techrobots TB6 series of co-robots ranges from 666 mm to 1500 mm, which can basically meet the torque requirements of different tightening situations. Among them, the TB6-R3 co-robot, small and light robots can meet the requirements of small space tightening. TB6 -The R20 co-robot can be applied to various large-load and long-arm display work areas due to its excellent high torque output performance and the development of a 1500 mm long arm.

Based on the characteristics of human-to-human collaboration, high safety, low cost, flexibility and ease of use, the collaborative machine greatly meets the high requirements of enterprises for flexible production.

1.3C scenario

As the world's largest 3C production base, the potential demand for robots in the 3C industry will reach 1 million in the future. Compared with Japan and South Korea, which have 1,200 3C industrial robots per 10,000 people, the number of robots in China's 3C industry is almost negligible. Some parts are automatically processed, and most of them are manufactured manually.

However, China’s industrial agglomeration and integration schemes are easy to standardize; the density of robots is the lowest and the room for growth is large; the competition of foundries is fierce and the demand is strong. Various good factors indicate that due to the explosive growth of the demand for robots in the 3C industry, the robot industry will be very The next industry explosion is coming soon.

Taking the mobile phone industry as an example, the requirements for mobile phone products are getting higher and higher and facing many challenges:

1. The parts are small in size, and most of the parts are millimeter-level;

2. Irregular parts, irregular parts (camera, cable, etc.);

3. There are many product styles and many product series;

4. The update cycle is fast, and a special device may not be suitable for new products after only a few months;

5. High appearance requirements, no slight scratches on the surface;

6. High-speed requirements, production efficiency is very important for mobile phone manufacturing;

7. The failure rate is low, and the failure will cause the whole line to stop production.

8. There is a shortage of skilled workers in the production line, a shortage of skilled workers, and unskilled skills;

9. Quality control is difficult, and production efficiency control is uncertain;

10. Labor wages are rising rapidly, and failures will cause the entire line to stop production;

11. Factors such as workers' emotionality, repetitive work, and sabotage will affect the production of products.

The six-axis and seven-axis co-robots developed and produced by Techrobots have certain advantages in certain applications. They can not only meet the automatic conversion of existing production lines in small spaces but are also very suitable for this labor-intensive industry." The need for man-machine collaboration.

They can automate many different applications.

They are small in size and light in weight and can be easily transferred to different processes in the workshop.

They are easy to program, and users can save programs for reuse.

2. Car scene

At present, many automobile companies are looking for solutions to increase the labor intensity of the production line, in order to increase the degree of production automation, increase production capacity, and thus bring added value to the production process. In today's Industry 4.0, automation solutions are not only the pursuit of mechanization, but also a new automation solution that pays more attention to safety, flexibility, and movement anytime and anywhere when needed, and also needs to achieve higher security To speed up the return on investment.

In order to fill the gaps in workers and improve production quality, Techrobots smart robots can tighten the engine block by tightening the end of the module, as well as an automatic screw supply system.

In the process of tightening the robot with the tightening gun, the screw automatic feed system controls the nail speed and reminds the lack of material through the control unit, the tightening module detects the position of the screw through the screw position sensor, and the electric CNC screwdriver uses the depth sensor to detect and torque monitor feedback If the screw is tightened, the robot can carry the tightening module to achieve multi-position and fast tightening work.

During the tightening process, the maximum torque that different co-robots can achieve is affected by the speed reducer used by the robot and the expansion of the arm. During the tightening process, the maximum torque that different co-robots can achieve is affected by the speed reducer used by the robot and the expansion of the arm.

Previous Article: New world of co-robot applications

Next Article: Co-robots will commit to more subdivided fields in the future