What are the differences between co-robot and traditional industrial robots?

Date:2020-04-10

Due to the reasons of the project and the main co-robot manufacturers on the market have had exchanges and investigations in various aspects, including Aobo, ur, abb, Techrobots, etc., and also participated in many Techrobots co-robot exhibitions. The understanding of co-robot is quite different from that of traditional industrial robot.

The first is that the load is different, and the co-robot tends to process precision machining, which also causes different application fields;

The second is the safe release and collision function of the co-robot, which can save the safety fence and ensure the safety of the operator; the other is the drag teaching function of the co-robot, which can be used directly without the operator fully mastering the programming language and simple training,

All robots need people's maintenance and adjustment, just how much they need. The more reliable and maneuverable the machine is, the less people need to worry about it.

There is no difference between traditional robots and co-robot in terms of repetitive prescribed actions. Only in this way can the degree of automation be high. The purpose of human-machine co-robot design is to overcome some shortcomings of traditional robots, and specialize in the market of more detailed fine operation and customized operation, which can not replace the traditional robots. Although it has not been widely used now, it mainly depends on the human load of cooperation machine, you know that large parts can not be processed.

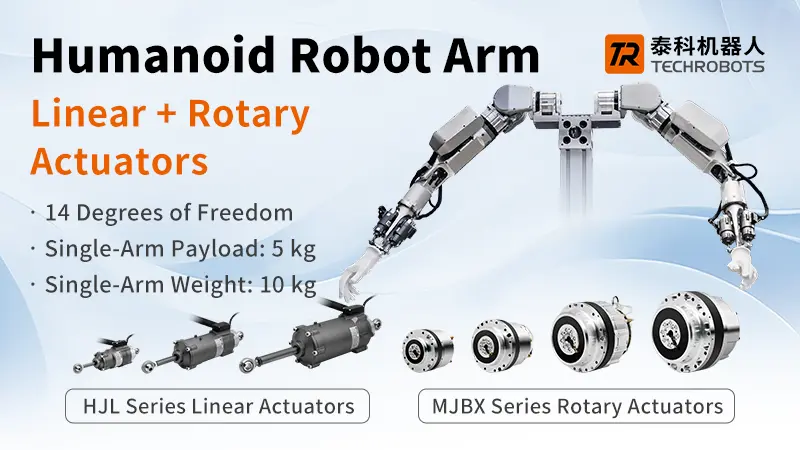

Small size is an advantage of co-robot. The premise of this advantage is that both co-robot and traditional industrial robot are competent for this task. Because of its small size, light weight, simple installation and debugging, the same machine can move in a relatively convenient position (two people can rearrange the tb6-r3 co-robot), and teach again, which greatly improves the flexibility of the production line and reduces the investment. On the other hand, if the position of traditional industrial robots changes a little, they need to manually hold the controller for half a day, let alone if they move the position for a new production process, the whole floor and fence need to be redone, which is basically the same trouble as reinstallation. Take Techrobotst as an example, because they know more about them, they also set up their own robot production plant in Shenzhen. In the research and development of co-robot, they started from the development and production of servo system and motion control system, to the transformation and production of joint modules of co-robot. At last, they focused on the research and development of co-robot, fully localized joint modules of robots, and co-robot. Because of their specialty, they are more focused. They are looking forward to the cooperation of Techrobots(ShenZhen) There are more breakthroughs and developments in the field of human application.

The first is that the load is different, and the co-robot tends to process precision machining, which also causes different application fields;

The second is the safe release and collision function of the co-robot, which can save the safety fence and ensure the safety of the operator; the other is the drag teaching function of the co-robot, which can be used directly without the operator fully mastering the programming language and simple training,

All robots need people's maintenance and adjustment, just how much they need. The more reliable and maneuverable the machine is, the less people need to worry about it.

There is no difference between traditional robots and co-robot in terms of repetitive prescribed actions. Only in this way can the degree of automation be high. The purpose of human-machine co-robot design is to overcome some shortcomings of traditional robots, and specialize in the market of more detailed fine operation and customized operation, which can not replace the traditional robots. Although it has not been widely used now, it mainly depends on the human load of cooperation machine, you know that large parts can not be processed.

Small size is an advantage of co-robot. The premise of this advantage is that both co-robot and traditional industrial robot are competent for this task. Because of its small size, light weight, simple installation and debugging, the same machine can move in a relatively convenient position (two people can rearrange the tb6-r3 co-robot), and teach again, which greatly improves the flexibility of the production line and reduces the investment. On the other hand, if the position of traditional industrial robots changes a little, they need to manually hold the controller for half a day, let alone if they move the position for a new production process, the whole floor and fence need to be redone, which is basically the same trouble as reinstallation. Take Techrobotst as an example, because they know more about them, they also set up their own robot production plant in Shenzhen. In the research and development of co-robot, they started from the development and production of servo system and motion control system, to the transformation and production of joint modules of co-robot. At last, they focused on the research and development of co-robot, fully localized joint modules of robots, and co-robot. Because of their specialty, they are more focused. They are looking forward to the cooperation of Techrobots(ShenZhen) There are more breakthroughs and developments in the field of human application.

Previous Article: Co-robot under smart factory

Next Article: Five special applications of co-robots