Offline programming is gradually unveiling the mystery of Robotics

Date:2019-10-15

Although offline programming (OLP) has come a long way, misunderstandings about it still exist. In the welding industry, many robot programming still need to be done manually point by point on the teaching attachments, which is extremely cumbersome. Many people remember the history of robotic technology. These robots promised too much, but in fact they couldn't achieve it. Dreamers and doers have been trying to exceed expectations.

Simulations and off-line programming software are also gradually developing and becoming more intelligent, faster, more flexible and more reliable. This is a new era advocating ease of use, offline programming software vendors are gradually unveiling the mystery of robotics technology.

Most simulation and offline programming solution providers will tell you that this is not a one-or-one option, and simulation and offline programming can go hand in hand. But that doesn't mean they can be used interchangeably. You can simulate without offline programming, but you can't use offline programming without simulation.

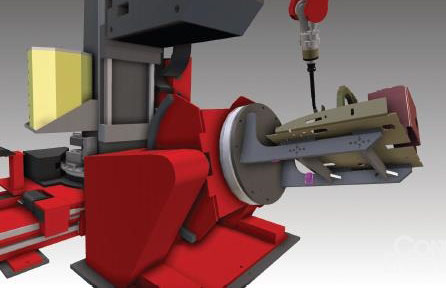

Fig. 1: Off-line programming software accurately simulates robot welding process by using the calibration data of robot kinematics, external axle and workpiece locator.

Robot simulation is a three-dimensional representation of a robot unit or production line. It intuitively demonstrates how the robot moves from one XYZ coordinate to another along a given path or trajectory. It can include a number of robots mounted on the outer axle, which can be used in conjunction with multi-axis workpiece locators, and can also be coordinated on the assembly line. However, all these sports and plans will become more complex.

"Many customers who buy robots think it behaves like a computer numerical control (CNC). This is not the case." RoboDK CEO Albert Nubiola said. "CNC programming is easy. The workspace has been correctly defined. It's like a cube." However, robots have a spherical workspace, and because of joint constraints and robotic singularities (points where robotic motion is mathematically unpredictable), there are some types of motion that you cannot achieve. Offline programming helps avoid errors in programming for robots.

There may be hundreds or thousands of points in robotic processing, Nubiola continues, "Nobody can program point-by-point using the teaching widget. You definitely need software to program offline.

Simulations can be used to validate concepts, such as sales tools for robotic integrators, to demonstrate how robotic systems work. Through simulation, users can detect possible conflicts between robots, tools, fixtures and any safety fence.

Simulations can analyze joint constraints, singularities and range problems. In addition, it can reveal a series of remarkable problems that can save time and money in the long run. Offline programming uses simulation to output specific robot code, which can be loaded into the controller of the actual robot and run the program. The post processor converts the programming code into a language that the robot can understand. Robot manufacturers have their own proprietary programming languages, which means that third-party software must be multilingual.

Benefits of offline programming

The main driving force of offline programming is to reduce the downtime of the robot, that is, the time needed to program the robot manually point by point with the teaching attachment, and the cost related to the downtime of the machine and the workforce of the programmer.

"If the end user manually programms robots on the teaching attachment (online), they must stop production to program the parts." Rob House, sales director of Octopuz, said, "The advantage of using offline programming is that you can program in production, offline in software for your second, third or fifth part, and then, once you are ready to start a new process, you can switch the program and start your production again."

Off-line programming is most suitable for complex path planning applications requiring a large number of points, such as welding, trimming, laser cutting, deburring, thermal spraying, spraying, laser cladding and augmentation manufacturing. Offline programming is not particularly useful for simple fetching and placing applications, assembly, packaging and palletizing. Although these applications can still be programmed using offline software, users may not be able to achieve a return on investment. Manual programming would be more economical if the process had only four to five points.

"For every new component, if you spend as much time on offline programming software as teaching widgets, it won't do you any good," said Garen Cakmak, senior director of Hypertherm Robotics Software. "For robots in high-mix, low-capacity environments, the software needs to be simple and easy to use."

Improving ease of use is the primary task of these software developers. But if simulation and offline programming can not accurately reflect the reality, then simulation and offline programming will be meaningless.

Figure 2: In railway maintenance, hundreds of repetitive actions are required. If off-line programming with cooperative robots is used, months of manual programming time can be saved.

Calibration and do not deviate

For offline programming to work, the virtual world must match the real world. This means that the simulation must accurately represent the physical robot unit.

"The virtual environment in offline programming software must completely replicate the actual unit of work in the workshop, but in most cases this is not the case." Helmut Ziewers, vice president of digital factory solutions at Cenit, said, "The deviation between a computer-aided design (CAD) model and its corresponding physical components may be small or large, especially when the tools used are not particularly perfect. We still see the main problem, because of these deviations, people think that these tasks can not be completed offline. However, these deviations are not insurmountable, so calibration is essential.

Figure 3: In the arc welding unit, if off-line programming is used, the programming time can be reduced by half, and the downtime of the robot can be reduced, thus helping to meet the production needs.

"Even with a few millimetres or centimeters of deviation, you can create any number of offline programs," Ziewers said. "They will never be exactly the same. We must know exactly how the robots in the workshop are set up, and there must be no deviation, otherwise offline programming will not work. Tool paths and trajectories will always be closed.

Crown equipment, which makes powered forklifts, has encountered such problems. Its Roding plant in Germany has a number of complex robotic welding systems with external axles and multi-axis workpiece locators. Faced with production bottlenecks caused by time-consuming manual robot programming, Crown decided to explore the feasibility of offline programming. Their journey was not smooth. Some of the Crown team are skeptical, while others are eager to try offline programming.

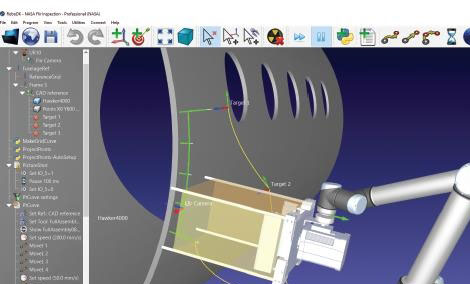

Figure 4: NASA is developing a new detection system, offline programming software for its simulation robot path planning. The system uses cooperative robots equipped with infrared cameras to test defects in composite aircraft structures.

Cenit is one of the two suppliers involved in the benchmark study. Ziewers said they used CAD drawings from Crown Automation Integrator and created virtual robotic units in their software. Based on these drawings, they created robotic programs and ran them on physical units of work.

Engineer Cenit went to the site personally to calibrate the working units of Crown Plant. "We found differences in size," Ziewers said. "We used these differences in software and then adjusted the offline program according to the new settings in the virtual world." This matches the physical settings of the workshop, and the robot program runs well.

Simulations and off-line programming software are also gradually developing and becoming more intelligent, faster, more flexible and more reliable. This is a new era advocating ease of use, offline programming software vendors are gradually unveiling the mystery of robotics technology.

Most simulation and offline programming solution providers will tell you that this is not a one-or-one option, and simulation and offline programming can go hand in hand. But that doesn't mean they can be used interchangeably. You can simulate without offline programming, but you can't use offline programming without simulation.

Fig. 1: Off-line programming software accurately simulates robot welding process by using the calibration data of robot kinematics, external axle and workpiece locator.

Robot simulation is a three-dimensional representation of a robot unit or production line. It intuitively demonstrates how the robot moves from one XYZ coordinate to another along a given path or trajectory. It can include a number of robots mounted on the outer axle, which can be used in conjunction with multi-axis workpiece locators, and can also be coordinated on the assembly line. However, all these sports and plans will become more complex.

"Many customers who buy robots think it behaves like a computer numerical control (CNC). This is not the case." RoboDK CEO Albert Nubiola said. "CNC programming is easy. The workspace has been correctly defined. It's like a cube." However, robots have a spherical workspace, and because of joint constraints and robotic singularities (points where robotic motion is mathematically unpredictable), there are some types of motion that you cannot achieve. Offline programming helps avoid errors in programming for robots.

There may be hundreds or thousands of points in robotic processing, Nubiola continues, "Nobody can program point-by-point using the teaching widget. You definitely need software to program offline.

Simulations can be used to validate concepts, such as sales tools for robotic integrators, to demonstrate how robotic systems work. Through simulation, users can detect possible conflicts between robots, tools, fixtures and any safety fence.

Simulations can analyze joint constraints, singularities and range problems. In addition, it can reveal a series of remarkable problems that can save time and money in the long run. Offline programming uses simulation to output specific robot code, which can be loaded into the controller of the actual robot and run the program. The post processor converts the programming code into a language that the robot can understand. Robot manufacturers have their own proprietary programming languages, which means that third-party software must be multilingual.

Benefits of offline programming

The main driving force of offline programming is to reduce the downtime of the robot, that is, the time needed to program the robot manually point by point with the teaching attachment, and the cost related to the downtime of the machine and the workforce of the programmer.

"If the end user manually programms robots on the teaching attachment (online), they must stop production to program the parts." Rob House, sales director of Octopuz, said, "The advantage of using offline programming is that you can program in production, offline in software for your second, third or fifth part, and then, once you are ready to start a new process, you can switch the program and start your production again."

Off-line programming is most suitable for complex path planning applications requiring a large number of points, such as welding, trimming, laser cutting, deburring, thermal spraying, spraying, laser cladding and augmentation manufacturing. Offline programming is not particularly useful for simple fetching and placing applications, assembly, packaging and palletizing. Although these applications can still be programmed using offline software, users may not be able to achieve a return on investment. Manual programming would be more economical if the process had only four to five points.

"For every new component, if you spend as much time on offline programming software as teaching widgets, it won't do you any good," said Garen Cakmak, senior director of Hypertherm Robotics Software. "For robots in high-mix, low-capacity environments, the software needs to be simple and easy to use."

Improving ease of use is the primary task of these software developers. But if simulation and offline programming can not accurately reflect the reality, then simulation and offline programming will be meaningless.

Figure 2: In railway maintenance, hundreds of repetitive actions are required. If off-line programming with cooperative robots is used, months of manual programming time can be saved.

Calibration and do not deviate

For offline programming to work, the virtual world must match the real world. This means that the simulation must accurately represent the physical robot unit.

"The virtual environment in offline programming software must completely replicate the actual unit of work in the workshop, but in most cases this is not the case." Helmut Ziewers, vice president of digital factory solutions at Cenit, said, "The deviation between a computer-aided design (CAD) model and its corresponding physical components may be small or large, especially when the tools used are not particularly perfect. We still see the main problem, because of these deviations, people think that these tasks can not be completed offline. However, these deviations are not insurmountable, so calibration is essential.

Figure 3: In the arc welding unit, if off-line programming is used, the programming time can be reduced by half, and the downtime of the robot can be reduced, thus helping to meet the production needs.

"Even with a few millimetres or centimeters of deviation, you can create any number of offline programs," Ziewers said. "They will never be exactly the same. We must know exactly how the robots in the workshop are set up, and there must be no deviation, otherwise offline programming will not work. Tool paths and trajectories will always be closed.

Crown equipment, which makes powered forklifts, has encountered such problems. Its Roding plant in Germany has a number of complex robotic welding systems with external axles and multi-axis workpiece locators. Faced with production bottlenecks caused by time-consuming manual robot programming, Crown decided to explore the feasibility of offline programming. Their journey was not smooth. Some of the Crown team are skeptical, while others are eager to try offline programming.

Figure 4: NASA is developing a new detection system, offline programming software for its simulation robot path planning. The system uses cooperative robots equipped with infrared cameras to test defects in composite aircraft structures.

Cenit is one of the two suppliers involved in the benchmark study. Ziewers said they used CAD drawings from Crown Automation Integrator and created virtual robotic units in their software. Based on these drawings, they created robotic programs and ran them on physical units of work.

Engineer Cenit went to the site personally to calibrate the working units of Crown Plant. "We found differences in size," Ziewers said. "We used these differences in software and then adjusted the offline program according to the new settings in the virtual world." This matches the physical settings of the workshop, and the robot program runs well.

Previous Article: Should cooperative robots do it?

Next Article: Chip card neck, how will Chinese intelligent robot crack?