Domestic independent research and development of joint module outstanding encirclement, parts to achieve full domestic

Date:2020-06-15

The disappearance of the demographic dividend is accompanied by the development of intelligent manufacturing, 5G, autopilot, and artificial intelligence. Robots will not only replace humans in the military, service, entertainment, and other fields but also workers in manufacturing. The robotics industry will also get a further boost. In the context of both opportunities and challenges, how to break the "import monopoly" and "technical barriers" of Chinese robot manufacturing enterprises is an urgent problem to be solved by domestic robot manufacturing enterprises.

The robot industry chain includes upstream raw materials, core components, ontology manufacturing, and system integration, among which the core components are the most important components of industrial robots and the core technical obstacles of robots.

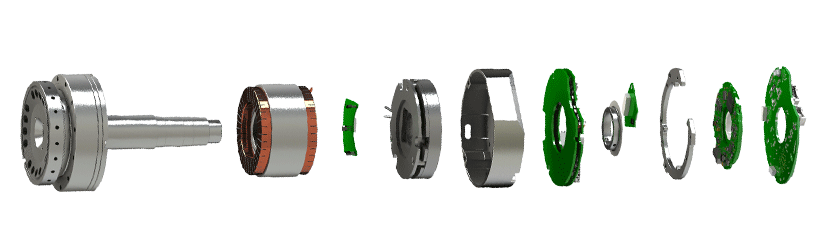

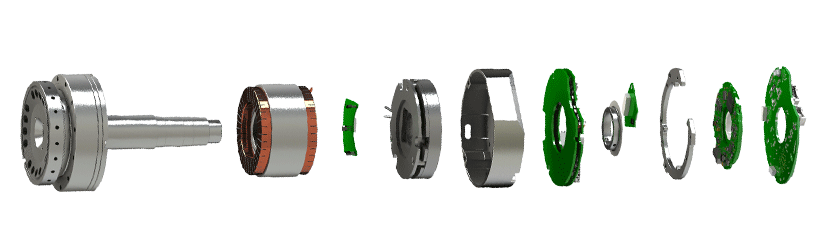

Techservo(Shenzhen) Co., Ltd. is a domestic manufacturer specializing in r&d and production of co-robot body and joint module. In the r&d and production of robot joint module, it has realized the complete localization of all parts and standardized production. Through the analysis of the internal mechanism and movement principle of the robot joint module for many times, the overall optimization of the joint module is carried out, so that the volume of the joint module is small and the result is more compact. The performance can compete with the joint module of foreign large manufacturers.

As is known to all, the intelligent robot is a kind of electromechanical integration products, it is composed of three parts, six subsystems, respectively is the mechanical part, sensor part, and control part, the six subsystems are: drive system, mechanical system, control system structure and human-computer interaction system, sensory systems, robot - environment interaction system.

The motor is a key link in the intelligent robot industry chain, and the robot joint is one of the components of the robot arm. With the expansion of the application range of robot joints, robot arms urgently need to be upgraded, which also puts forward higher requirements for the motor. The existing manipulator motor has many specifications, small-batch, poor versatility, high cost, quality, and reliability instability. The range of tasks a robotic arm can accomplish is limited by its mechanical structure. The structure optimization of the robotic arm is one of the key technologies to solve this problem.

At present, the demand for robots in the domestic market is growing rapidly, driving the rapid growth of new demand for robot joint gear reducer, with a compound annual growth rate of nearly 20%. It is estimated that by 2025, the global market sales scale of the precision reducer will exceed 60 billion yuan, of which the world market sales scale will exceed 1/4.

The joint reducer is one of the core components of the robot, and the integration of the downstream system is the key to the commercialization and large-scale promotion of the robot. At present, there are few manufacturers of robot reducer with large scale and reliable performance in the world, and most of the global market share is occupied by Japanese enterprises. Although the price of domestic robot reducer is cheap and the supply cycle is short, there is a big gap between the performance of domestic robot reducer and that of foreign products. Therefore, most of the domestic reducer can only be used for medium and low-end robots, unable to meet the market demand for high-end robots. The breakthrough of "technical barrier" is the only way for domestic robot manufacturers to go to the blue sea. Zhao's joint steering gear engages with a large gear on the output shaft through a small gear on the input shaft to reduce speed and improve torque, thus improving dynamic performance. The robot itself is the basis of the development of the robotic industry, and the downstream system integration is the key to the commercialization and large-scale promotion of robots.

By continuously coding the microdrive system and precision gear parts, the parameters, functions, and components of robot joint parts will be adjusted and optimized constantly, and the products of the microdrive will become more and more mature. In terms of intelligent drive systems, Zhao Wei provides the most intelligent robot manufacturers with customized solutions for microdrive systems and electronic drive modules. Robot manufacturers can design and customize suitable joint modules according to different axis number and motion requirements. Zhao's goal is to lower the manufacturing threshold for robot joints, help Chinese robot makers create truly competitive and differentiated domestic robots, rewrite the robot industry model, and help the country's intelligent manufacturing process help "arms." With the upgrading of domestic consumption, the acceleration of social aging, labor shortage, rising labor costs, and the development of science and technology, China's demand for robots is gradually increasing, especially in the fields of family, education, and public services. The demand for robots continues to be strong, and the future market demand for robots has great potential. Through the upgrading of product structure "joint" components break through the international market, facing the new blue sea, which is becoming the direction of domestic robot manufacturing efforts and thinking.

The robot industry chain includes upstream raw materials, core components, ontology manufacturing, and system integration, among which the core components are the most important components of industrial robots and the core technical obstacles of robots.

Techservo(Shenzhen) Co., Ltd. is a domestic manufacturer specializing in r&d and production of co-robot body and joint module. In the r&d and production of robot joint module, it has realized the complete localization of all parts and standardized production. Through the analysis of the internal mechanism and movement principle of the robot joint module for many times, the overall optimization of the joint module is carried out, so that the volume of the joint module is small and the result is more compact. The performance can compete with the joint module of foreign large manufacturers.

As is known to all, the intelligent robot is a kind of electromechanical integration products, it is composed of three parts, six subsystems, respectively is the mechanical part, sensor part, and control part, the six subsystems are: drive system, mechanical system, control system structure and human-computer interaction system, sensory systems, robot - environment interaction system.

The motor is a key link in the intelligent robot industry chain, and the robot joint is one of the components of the robot arm. With the expansion of the application range of robot joints, robot arms urgently need to be upgraded, which also puts forward higher requirements for the motor. The existing manipulator motor has many specifications, small-batch, poor versatility, high cost, quality, and reliability instability. The range of tasks a robotic arm can accomplish is limited by its mechanical structure. The structure optimization of the robotic arm is one of the key technologies to solve this problem.

At present, the demand for robots in the domestic market is growing rapidly, driving the rapid growth of new demand for robot joint gear reducer, with a compound annual growth rate of nearly 20%. It is estimated that by 2025, the global market sales scale of the precision reducer will exceed 60 billion yuan, of which the world market sales scale will exceed 1/4.

The joint reducer is one of the core components of the robot, and the integration of the downstream system is the key to the commercialization and large-scale promotion of the robot. At present, there are few manufacturers of robot reducer with large scale and reliable performance in the world, and most of the global market share is occupied by Japanese enterprises. Although the price of domestic robot reducer is cheap and the supply cycle is short, there is a big gap between the performance of domestic robot reducer and that of foreign products. Therefore, most of the domestic reducer can only be used for medium and low-end robots, unable to meet the market demand for high-end robots. The breakthrough of "technical barrier" is the only way for domestic robot manufacturers to go to the blue sea. Zhao's joint steering gear engages with a large gear on the output shaft through a small gear on the input shaft to reduce speed and improve torque, thus improving dynamic performance. The robot itself is the basis of the development of the robotic industry, and the downstream system integration is the key to the commercialization and large-scale promotion of robots.

By continuously coding the microdrive system and precision gear parts, the parameters, functions, and components of robot joint parts will be adjusted and optimized constantly, and the products of the microdrive will become more and more mature. In terms of intelligent drive systems, Zhao Wei provides the most intelligent robot manufacturers with customized solutions for microdrive systems and electronic drive modules. Robot manufacturers can design and customize suitable joint modules according to different axis number and motion requirements. Zhao's goal is to lower the manufacturing threshold for robot joints, help Chinese robot makers create truly competitive and differentiated domestic robots, rewrite the robot industry model, and help the country's intelligent manufacturing process help "arms." With the upgrading of domestic consumption, the acceleration of social aging, labor shortage, rising labor costs, and the development of science and technology, China's demand for robots is gradually increasing, especially in the fields of family, education, and public services. The demand for robots continues to be strong, and the future market demand for robots has great potential. Through the upgrading of product structure "joint" components break through the international market, facing the new blue sea, which is becoming the direction of domestic robot manufacturing efforts and thinking.

Previous Article: RJSII series joint modules help Gree quickly build coffee robots

Next Article: Everyone says that co-robot are cost-effective, where is it?