Faced with difficulties, how do domestic robots face opportunities and challenges?

Date:2020-04-29

With the continuous development of the globalization trend, high-quality, low-price "Made in China" once penetrated all over the world, but with the appreciation of the RMB, the reduction of export tariffs, the increase in the cost of labor and raw materials, and the Sino-US trade friction As a result, China's manufacturing industry are facing huge challenges.

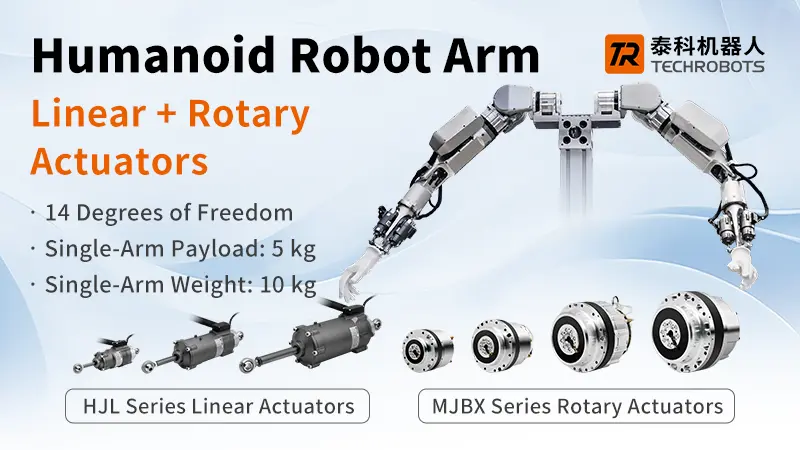

As a company with co-robot and joint modules as its main business, Techrobots(Shenzhen) mainly explains the difficulties encountered by China's manufacturing industry from the perspective of "people". As the birth rate in China has declined, statistics show that the post-80s generation is nearly 100 million fewer than the post-80s generation, but there are also about 100 million people in China ’s manufacturing industry, including high-end scientific research personnel, which means that they are willing to enter in the future. There are fewer and fewer young people in factories, and the manufacturing industry faces a huge employment gap. The application of co-robot is essential.

As we all know, in the field of automobile manufacturing and 3C manufacturing, the proportion of automation is already very high, and the application of co-robot is also more mature. However, under the premise of diversified manufacturing structure and complex industrial structure in China, the robot industry is also different, which means that there will also be demand in other fields. How to reflect the innovation of co-robot? The specific manifestation of the differentiation of the robot industry is: looking for new features in mature applications, and new areas that co-robot have not used in the past. Han Fengtao said.

Taking Techrobots as an example, since 2016, the company has developed a joint robot joint module based on the strong technical foundation of a low-voltage servo system. "In 2019, a series of robot motors, servo drives, locks, incremental/absolute encoders, RJS / RJSII / RJU / SHD series robot joint modules, Ta6 / TB6 series 6-axis co-robot, etc. were developed and widely used in factories Automation, automotive, 3C, medical, power, aerospace, scientific research, education, and other fields.

When talking about the development path of co-robot is in line with national conditions and sustainable development, Techrobots(Shenzhen) believes that co-robot will always be divided into high, medium, and low-end. In most cases, the price is not even the primary concern of customers Factors, quality, and low price, the focus is not cheap, but quality, and the quality of domestic core components and home robots are not necessarily related.

In addition to Techrobots(Shenzhen), executives and company representatives of Wuhan Kubert Technology Co., Ltd. Co., Ltd., Elliott Robot, Shandong Times New Era Robot, Beijing Luoshi, Anhui Sky Matching Robot, Huanyan Automation Equipment (Shanghai) Co., Ltd. Ningbo Poseidon Robot Technology Co., Ltd. The company expounded the company's operating status and achievements in related fields from their respective perspectives. It can be seen that domestic robots have made certain breakthroughs in application fields and technical levels, and will surely be rapidly developed in the future.

As a company with co-robot and joint modules as its main business, Techrobots(Shenzhen) mainly explains the difficulties encountered by China's manufacturing industry from the perspective of "people". As the birth rate in China has declined, statistics show that the post-80s generation is nearly 100 million fewer than the post-80s generation, but there are also about 100 million people in China ’s manufacturing industry, including high-end scientific research personnel, which means that they are willing to enter in the future. There are fewer and fewer young people in factories, and the manufacturing industry faces a huge employment gap. The application of co-robot is essential.

As we all know, in the field of automobile manufacturing and 3C manufacturing, the proportion of automation is already very high, and the application of co-robot is also more mature. However, under the premise of diversified manufacturing structure and complex industrial structure in China, the robot industry is also different, which means that there will also be demand in other fields. How to reflect the innovation of co-robot? The specific manifestation of the differentiation of the robot industry is: looking for new features in mature applications, and new areas that co-robot have not used in the past. Han Fengtao said.

Taking Techrobots as an example, since 2016, the company has developed a joint robot joint module based on the strong technical foundation of a low-voltage servo system. "In 2019, a series of robot motors, servo drives, locks, incremental/absolute encoders, RJS / RJSII / RJU / SHD series robot joint modules, Ta6 / TB6 series 6-axis co-robot, etc. were developed and widely used in factories Automation, automotive, 3C, medical, power, aerospace, scientific research, education, and other fields.

When talking about the development path of co-robot is in line with national conditions and sustainable development, Techrobots(Shenzhen) believes that co-robot will always be divided into high, medium, and low-end. In most cases, the price is not even the primary concern of customers Factors, quality, and low price, the focus is not cheap, but quality, and the quality of domestic core components and home robots are not necessarily related.

In addition to Techrobots(Shenzhen), executives and company representatives of Wuhan Kubert Technology Co., Ltd. Co., Ltd., Elliott Robot, Shandong Times New Era Robot, Beijing Luoshi, Anhui Sky Matching Robot, Huanyan Automation Equipment (Shanghai) Co., Ltd. Ningbo Poseidon Robot Technology Co., Ltd. The company expounded the company's operating status and achievements in related fields from their respective perspectives. It can be seen that domestic robots have made certain breakthroughs in application fields and technical levels, and will surely be rapidly developed in the future.

Previous Article: Human-machine collaboration, see how domestic co-robot power enterprise automation upgrade

Next Article: Thanksgiving 2019, hand in hand 2020