Navigating the humanoid robot track, Tech Robots launches a heavyweight joint module

Date:2023-11-20n recent years, the field of humanoid robots has become increasingly popular, witnessing the emergence of heavyweight products and the continuous entry of industry giants. Internationally, Tesla's Optimus Prime has stirred waves of excitement, while domestically, major players like Xiaomi, Utree, Zhiyuan, Zhuimi, Xiaopeng, iFLYTEK, and many others have joined the competition. Recently, the Ministry of Industry and Information Technology issued the "Guidance on Innovative Development of Humanoid Robots," further intensifying the enthusiasm in the industry.

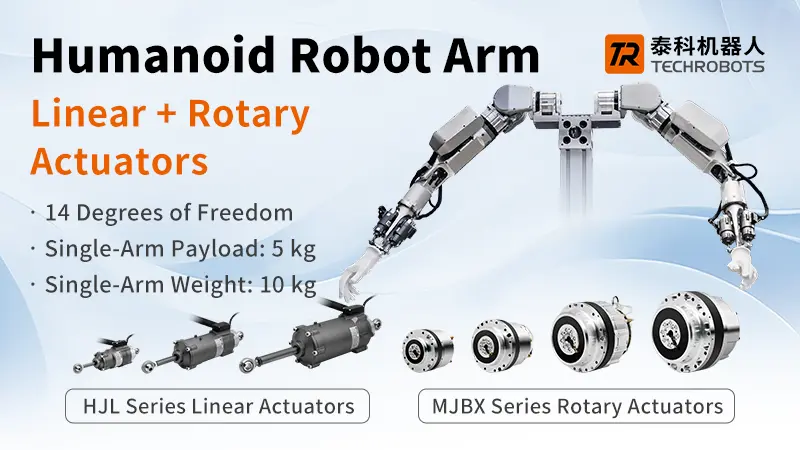

Recognizing the potential of humanoid robots as a hotspot several years ago, TechSmart Robotics decided to develop joint modules suitable for humanoid robots. After overcoming technical challenges, TechSmart Robotics has successfully launched a series of groundbreaking products. Let's take a closer look at each of them!

As early as 2016, Tech Robots began the research and production of joint modules. Benefiting from profound expertise in servo drive technology, the company successively developed classic joint products such as RJS, RJSII, and RJSIIZ. Subsequently, the R&D team, advancing their technical capabilities, initiated the development of iterative products. Aligning with the overarching trend of development, Tech Robots targeted the rapidly growing field of humanoid robots for the future. They focused on breaking through the ultimate power density under extremely compact size. Striving for every bit, reducing weight to 1g and compressing dimensions to 1mm, the result is the birth of Tech Robots' third-generation joint module, the MJX series:

The MJX series joint module weighs as light as 0.63kg, with a maximum torque of 48N·m, a minimum diameter of 69mm, a maximum speed of 45rpm, and a repeat positioning accuracy of <60arcsec—excellent in all aspects. It is not only the culmination of 15 years of Tech Robots' technology but also a breakthrough in related domestic products! With the MJX joint module, assembling humanoid robots, dual-arm robots, seven-axis collaborative robots, and more becomes simple and easy, catering to scenarios in the service industry, healthcare, 3C, and beyond.

II. DJB Series Joint Module

In contrast to the positioning of the MJX series joint modules, the DJB series products are explicitly designed and developed for quadrupedal robotic dogs and humanoid robots. While not reaching the extreme compactness of the MJX series in terms of volume and weight, the DJB series exhibits robust performance in terms of torque-to-weight ratio and load torque. Weighing only 1.45kg, it can deliver a maximum torque of 160N·m at a maximum speed of 100rpm, providing ample power and the capability to traverse complex terrains.

Due to the inherent characteristics of quadruped robotic dogs, such as a low center of gravity, high balance and flexibility, strong carrying capacity, adaptability, good traversing ability in complex terrains, etc., the application scenarios for DJB series are very diverse:

Public Spaces: Can serve as a service robot providing navigation, consultation, reception, and other services.

Industrial Production: Suitable for tasks like material handling, packaging, stacking, etc., to improve production efficiency and reduce costs.

Rescue and Public Safety: In disaster scenes or public safety scenarios, it can be used for search and rescue, improving work efficiency and safety.

Household and Pet Companionship: Functions as a pet companion, home assistant, providing entertainment, companionship, caregiving services.

In summary, the DJB series has a wide range of applications. Besides being used as a robotic dog, it can also serve as joints requiring high torque output in humanoid robots.

The field of humanoid robots is gaining popularity. Despite the participation of various industry giants, there are inherent advantages and significance in application areas. However, achieving large-scale commercialization is still in its early stages, with many technological barriers to overcome, including the need to improve energy density, breakthroughs in AI intelligence computing power and algorithms, and the challenge of cost reduction. Therefore, the road to commercializing and popularizing humanoid robots is still challenging.

Continuously striving for innovation and overcoming challenges, Tech Robots will transform technological advantages into advanced products. We look forward to joining hands with both new and existing customers, contributing to the advancement of intelligent manufacturing in China!