Empowering textile enterprises to achieve intelligent upgrades!

2021-07-21In recent years, the textile industry has embraced intelligence through the automation of equipment and continuous production. Tech Robots' joint modules and collaborative robots offer a comprehensive solution, helping textile enterprises achieve smart upgrades. This addresses issues like labor shortages and high costs, optimizing cost structures for increased efficiency and worry-free production.

1. Automatic Yarn Dropping

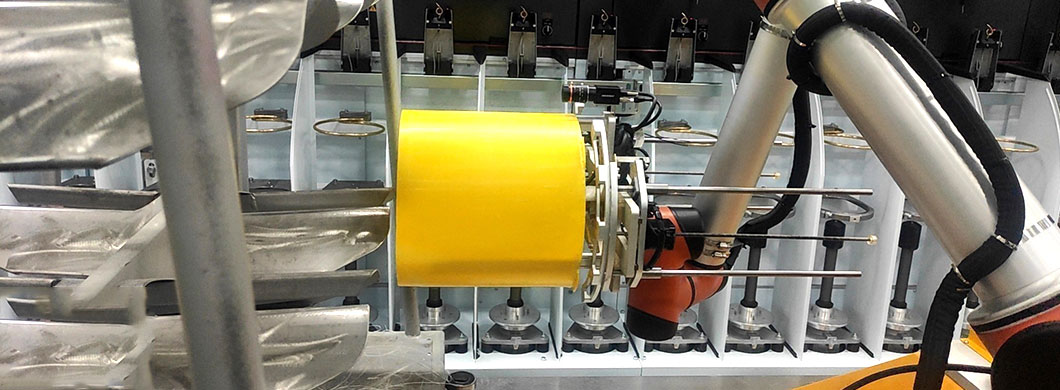

When fine yarn is full in the tube, the yarn-dropping robot moves smoothly along the channel, accurately grabbing the yarn tube and placing it in the basket. It then quickly inserts empty tubes onto the spindles. The yarn-dropping robot is a robust addition to the collective yarn-dropping system. Its flexible application can replace traditional manual tasks, reducing labor intensity, improving efficiency, and cutting production costs. Currently, Tech Robots' collaborative robots can handle the workload equivalent to 8 operators, saving about 50% in labor costs with doubled efficiency.

2.Automatic Bobbin Yarn Packaging

After the winding process, the robot automates bagging, sealing, weighing, labeling, and transferring bobbin yarn, reducing manual labor. Machine vision locates and protects the yarn, while IoT technology provides real-time marking for logistics and sales management.

3. Automatic Coarse Yarn Placement

The robot comprises a gripping arm, a hoisting arm, an empty tube conveyor system, and an AGV car. The AGV car positions itself automatically, and the high-precision gripping arm ensures efficient and accurate coarse yarn placement. With a precision level of ±0.05mm, Tech Robots significantly boost production line efficiency, making them suitable for both new machines and retrofitting existing ones in cotton spinning enterprises. This enhances automation, cuts labor costs, and improves overall production efficiency.

4. The Automation Revolution is Happening Now, Not Just in the Future

In recent years, rapid advancements in science and technology have propelled the textile industry forward with new technologies, materials, processes, and equipment. Automation achievements include automatic tube changing in carding, combing, and coarse yarn placement, as well as automatic splicing in ring spinning, air-jet spinning, and winding. The complexity of textile production lines demands high intelligence from robots. Tech Robots intelligent robots offer tailored solutions to meet the stringent technical requirements of different industries based on their processes and production.

Previous Article: Intelligent Ultrasonic Inspection Robot

Next Article: TB6-R10 Special Rescue Robot