Key Technical Factors for Selecting High-Performance Humanoid Robot Actuators

Date:2025-10-27Humanoid robot actuators are precision components that integrate transmission mechanisms, drivers, motors, brakes, encoders, and torque sensors. They serve as the core execution units responsible for driving and controlling precise anthropomorphic movements in each joint. Their performance directly determines the robot's motion capabilities, efficiency, and reliability. Humanoid robots impose stringent requirements on actuators that differ from those of traditional industrial robots, particularly in areas such as high torque density, precise control, dynamic response, energy efficiency, and structural robustness.

The following technical factors are decisive in selecting actuators for humanoid robots:

1. Torque Density: The Core Metric for Performance and Lightweight Design

Torque density measures an actuator's ability to deliver torque per unit mass. Humanoid robots feature numerous actuators (with advanced designs incorporating 16–60 degrees of freedom), and their weight directly impacts overall mass distribution, inertial loads, and energy consumption. Higher torque density enables lighter actuators with equivalent output, significantly reducing the robot's total weight, optimizing center of gravity, enhancing dynamic response speed, and extending battery life—ultimately improving payload capacity and overall motion performance.

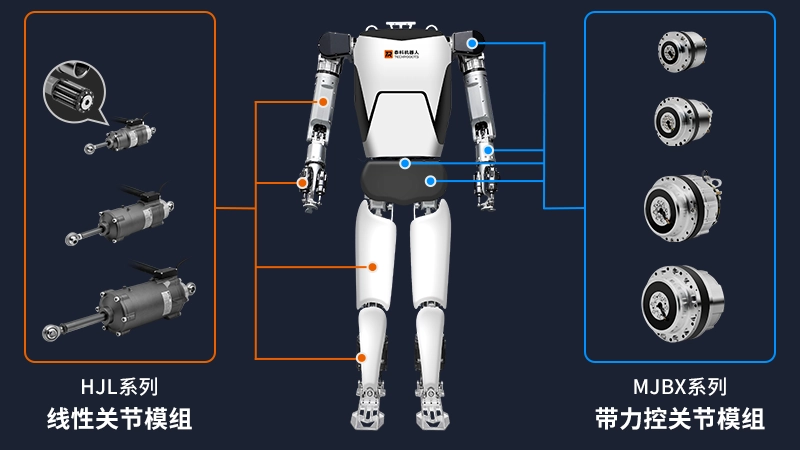

The Techrobots MJBX Series rotary actuators integrate optional torque sensors and employ an innovative harmonic reducer design for lightweight yet high-torque output (minimum weight: 0.84 kg), achieving a torque density of 57.8 N·m/kg. This allows real-time force and torque sensing across all joints in humanoid robots.

The HJL Series linear actuators utilize planetary roller screw transmission, delivering 600 N thrust at 0.5 kg or up to 8,000 N in heavier models (2.8 kg), with integrated tension/compression sensors. They are ideal for high-load areas like legs and arms, enhancing motion reliability and disturbance rejection.

2. Position and Torque Control Precision: The Foundation of Motion Accuracy

Actuator precision in position and torque control is essential for achieving smooth, coordinated movements. Each joint's spatial pose is defined by a three-dimensional vector, and minor errors can accumulate in multi-joint serial structures, causing end-effectors to deviate from target trajectories or destabilize postures (e.g., deviations in hip-knee-ankle coordination during gait). High precision relies on high-resolution encoders, advanced servo drive algorithms, low-backlash reducers, and multi-pole motors.

The Techrobots MJBX Series actuators, with integrated torque sensors, enable real-time capture of joint force data—such as grasping weight or collision reactions—providing the basis for "force perception" in humanoid robots. This achieves full-joint force awareness, where any body contact triggers torque sensor feedback. Such capabilities are crucial for natural, fluid motions like compliant interactions and delicate operations.

3. Dynamic Response and Overload Capacity: Essential for Complex Environments

Dynamic response refers to an actuator's ability to quickly follow control commands, measured by bandwidth and step response time. Overload capacity is the maximum instantaneous torque, far exceeding rated values in millisecond bursts. In unstructured environments, humanoid robots must rapidly adjust postures for events like ground subsidence or collisions, requiring actuators to deliver high torque instantaneously (e.g., for emergency foot placement adjustments) while stabilizing quickly.

This depends on high-power-density motors, instantaneous current output from drivers, and rigid transmission mechanisms. Techrobots actuators are designed to meet these dynamic demands, ensuring reliable high-torque bursts in emergencies.

4. Energy Efficiency and Thermal Management: Ensuring Endurance and Reliable Operation

Energy efficiency measures the ratio of electrical input converted to mechanical work, with losses primarily as heat. High efficiency reduces waste and heat generation, extending battery-powered humanoid robots' operational time. Thermal management controls temperature rise during sustained or high-load operation, as overheating can trigger protections, degrade performance, or cause damage.

Techrobots actuators enhance efficiency through refined designs, such as lightweight construction to minimize inertial loads, optimized electromagnetic configurations, and high-efficiency components (e.g., proprietary servo drivers reaching 95% efficiency). They also incorporate effective heat dissipation paths and management strategies, ensuring stable performance during prolonged high-load tasks—critical for continuous real-world applications.

5. Structural Robustness and Reliability: Guaranteeing Long-Term Stability

Structural robustness is an actuator's resistance to mechanical shocks, vibrations, and drops. Reliability encompasses long lifespan, low-maintenance design, and tolerance for harsh environments. Humanoid robots face risks like falls, collisions, and sudden loads during testing or applications (e.g., industrial handling or field inspections), so actuators—as core motion components—must offer exceptional mechanical durability and environmental resilience.

Techrobots actuators prioritize ruggedness, using high-quality materials and reinforced structures to withstand drop tests, heavy lifting, and sudden impacts, ensuring sustained reliability, reduced maintenance, and overall functional integrity.

Balancing Standardized Actuators with Customized Solutions

Humanoid robot manufacturers often focus their core competencies on AI algorithms and software systems, while developing high-performance, highly integrated actuators involves complex system engineering. Partnering with experts in robotic hardware—particularly actuators—with deep technical expertise and forward-design capabilities (such as Techrobots) can provide mature, reliable standardized or customized solutions. This accelerates product development, allowing clients to concentrate on their strengths and gain a time advantage in the embodied intelligence industrialization race. With years of experience in customizing robot bodies and actuators, Techrobots offers such critical technical support to clients.